Silver-free thick film copper technology

Bonding metal ceramic substrates

André Schwöbel, Benjamin Fabian, Daniel Schnee, Miriam Rauer, Anton Miric, Stefan Gunst

High power electronics have become one of the fastest growing market segments of the semiconductor industry. Major applications include motor drives, hybrid/electric vehicles, rail traction, wind turbines, and photovoltaics inverters. Because the power electronic modules used in these applications operate at high voltage and high current density, they must handle high temperatures and harsh conditions. One of the key components for highly reliable power electronic modules is a reliable metal ceramic substrate. To provide reliable functionality during operation, the substrate materials must provide outstanding electrical, thermal, insulation and mechanical performance. Additionally, they must work with commonly used assembly and interconnection technologies like soldering, sintering, and wire bonding.

Due to cost efficiency, Al2O3-based metal ceramic substrates, i.e. direct copper bonded substrates, are often used for power module manufacturing [1]. However, Al2O3-based ceramic cannot fully leverage the potential of wide bandgap semiconductors. As a result, silicon nitride Si3N4-based metal ceramic substrates are gaining popularity as materials for power module assembly. Si3N4 shows superior mechanical properties combined with high thermal conductivity [2].

Highly reliable Si3N4-based substrates are typically manufactured with active metal brazing (AMB) technology that uses Ag-filled and active metal (i.e. Titanium) containing brazing pastes [3]. The precious metal content in the brazing paste and a slow vacuum brazing process are the major price drivers for AMB substrates. Heraeus Electronics, however, has developed a design-to-cost, highly reliable Ag-free thick film copper bonding (TFCB®) technology for joining nitride-based ceramics with Cu foils. The paste eliminates the use of an expensive vacuum-based brazing technology. But how does TCFB perform compared to the industry-benchmark AMB substrate?

To compare the performance of TFCB to AMB, various reliability- and application-related tests such as thermal shock (-65°C/+150°C), peel strength, high temperature storage (175°C, 1000 hours) and partial discharge tests were conducted. Results of the experiments follow.

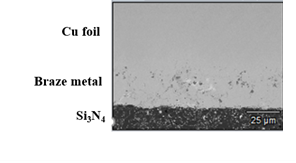

Phase Formation

The phase formation and bonding mechanism of TFCB technology on Si3N4 ceramics were characterized by scanning electron microscopy (SEM) as shown in Figure 1. The actual bonding mechanism is based on the reaction between the active metal (Titanium) and the Si3N4 ceramic, forming a stable TiN layer. Because there is no silver in the TFCB system, typical Ag- and Cu-rich phases are eliminated, which are known from the standard AMB technology as using high Ag-containing brazing filler metal pastes. Nevertheless, the bonding mechanism towards the Si3N4 ceramic via a TiN reaction layer is similar.

Thermal Shock Performance

Si3N4-based AMB substrates meet the highest requirements in terms of thermal shock test (TST) performance because of the ceramic’s mechanical robustness. To assess resistance vs. thermomechanical stress of TFCB on Si3N4 ceramics, thermal shock tests were performed using an internal test layout (30.6×29 mm2 with 0.5 mm Cu on 0.32 mm ceramic) as shown in Figure 2. The status of the TFCB substrates before testing was characterized by scanning acoustic microscopy (SAM) and is shown on the left of Figure 2.

The red color indicates an etched isolation groove that is part of the used test layout. In case of delamination between copper and braze metal/ceramic due to thermal shock, the red colored isolation groove will broaden in the SAM picture. The integrity of the substrates was reassessed by SAM after 3000 and 5000 cycles of thermal shock. The results are shown in the center and right of Figure 2 and illustrate no major broadening of the isolation grooves between the initial status of the TFCB and the cycled TFCB, proving that no delamination between the ceramic and the braze metal occurred. This indicates that the TFCB technology can fully leverage the mechanical robustness of the Si3N4 ceramics, the same as AMB technology.

Copper Peel Strength

The copper peel strength characterizes the adhesion strength of the Cu foil to the ceramic. A simple peel test is used in which a Cu peel strip (10 mm wide x 0.3 mm thick) is brazed onto a piece of 0.32 mm thick Si3N4 ceramic using the TFCB technology. The Cu is peeled off and the force is measured. Figure 3 shows an example of a peel test sample post-peel. The peel strength of this sample was 105 N/cm on average. The peel strength strongly depends on the substrate type and technology being tested.

Closer inspection of the failure mode of the peel sample can provide valuable information about the bonding quality. Figure 3 shows the peeled-off Cu strip after the peel test (right side) and the remaining substrate counterpart. A dark color on the peel strip and on the counterpart is visible, which indicates pulling out Si3N4 particles from the ceramic substrate. This failure mode is also often observed for Si3N4 AMB substrates. However, there is no failure within the reaction zone of the TFCB substrate. This is proven by EDS phase mapping (Figure 4) that shows most of the remaining material on the peel strip originates from the Si3N4 ceramic and not from the braze metal, indicating the strong bonding mechanism achieved by the TFCB process.

Thermal Resistance

The thermal resistance Rth of the metal ceramic substrate is an important factor for the design of the power module. A lower thermal resistance enables a higher power density, allowing reduced chip size. Major contributors to the Rth are Cu and ceramic thickness as well as ceramic type. TFCB interface formation is different than AMB and, therefore, it is required to rule out any potential Rth contribution from the braze metal or reaction zone itself.

The transient dual interface method was used to assess the thermal resistance of the metal ceramic substrates. Diodes were sintered onto both AMB and TFCB substrates, and the cumulative structure function was calculated from cooling curve measurements after heating the assembly by powering the diode with 40 A. The Rth of the system was then assessed by detecting the point of divergence of two structure functions measured under different boundary conditions, i.e. the assembly was connected by two different thermal interface materials (TIM) – graphite foil and thermal grease – to the cooling system

. The resulting structure functions are shown in Figure 5. The point of divergence is similar for both substrate types, demonstrating that there is no difference in thermal performance between AMB substrates and TFCB substrates in the initial status. Afterwards, the TFCB substrates were aged in a high-temperature storage (HTS) test for 1000 hours at 175°C to stress the braze metal and prove that the brazing filler metal system is stable. No difference was observed between the initial status and the aged substrate after HTS, showing that the alloy system displays no degradation and consistent values after 1000 hours of aging at 175°C.

Thermal Resistance Simulation

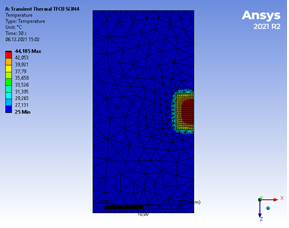

A thermal simulation was performed to assess the influence of thermal conductivity and the thickness of the braze metal layers in the substrate on its total thermal resistance. To include heat spreading and other geometrical effects, a Finite Element Method (FEM) was applied. A simplified geometry of a typical chip-substrate-setup was simulated, including the substrate itself, the braze metal layers on each side of the ceramic/Cu-interfaces, and a silicon chip with a sintered silver die attach (Figure 6).

In the simulation, the chip is heated by a constant power of 200 W in its volume for 30 s while the bottom of the substrate is kept at a constant temperature of 25°C. To assess the impact of thermal conductivity and braze metal layer thickness on thermal performance of the TFCB, both parameters were varied and Rth of the chip tracked as a basic result. The Rth was calculated based on the simulated maximum chip temperature change dTJ and the applied power. Typically, the region close to the chip is heated up the most while regions further away do not show a significant temperature change (Figure 7).

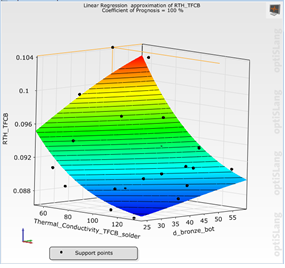

As a next step, a numerical Design of Experiments (DoE) was conducted. The goal was to identify which of the varied parameters (thermal conductivity and thickness of the braze metal layers) had the highest impact on the Rth of the substrate. For this DoE, an OPTISLANG program created 30 simulations distributed across the total design space as defined by the parameter’s boundaries. Having calculated these results and determined their Rth, a reduced order model was created that allows for a ranking of the influence of the input parameters (thermal conductivity and thickness) to the result (thermal resistance). The intervals for the parameters used for simulation are shown in the table

Table: Overview of properties used for FEM simulation.

| Min | Max | |

| Thickness of the braze metal layer (µm) | 20 | 60 |

| Thermal conductivity of braze metal (W/mK) | 51 | 140 |

The thermal conductivity of the braze metal layer is defined by its composition, which is approximated by a bronze of composition CuSnx. [7]. Typical variations of the braze metal layer thicknesses are in the order of 20 to 60 µm and were estimated by cross sections of samples and subsequent secondary electron microscopy analysis.

The correlation between thermal conductivity of the braze metal layer, the thickness of the braze metal layer and the corresponding thermal resistance can be observed in the surface plot in Figure 8. The main influencing factor is the thermal conductivity of the braze metal layer. The strongest change of the Rth is observed in the region towards lower thermal conductivities while the influence is reduced for higher values. The Rth values extracted from Figure 8 vary between 0.088 to 0.104 K/W using the input from the table. Comparing this theoretical range with the measurement results of (0.13 ± 0.03) K/W shows that experimental and simulated values are in agreement. It can be stated that an overall thermal understanding of the TFCB substrate was accomplished.

Conclusion

The performance of Heraeus Electronics’ TFCB technology was demonstrated by thermal shock, peel strength, partial discharge, thermal measurements and by thermal simulations. The investigations demonstrate that the TFCB technology enables cost-efficient but highly reliable metal ceramic substrate manufacturing using Ag-free TFCB paste, and a non-vacuum based brazing process.

André Schwöbel, Benjamin Fabian, Daniel Schnee, Miriam Rauer, Anton Miric, Stefan Gunst