Looking around us, we see more and more applications for fuel cell technology gaining traction. Examples are more than 300.000 µ-Combined Heat and Power installations in Japan, and more than 30.000 fuel cell-powered forklifts in the US. In the transportation sector, OEMs like Toyota, Honda and Hyundai have introduced fuel cell electric vehicles to the market – and the interest in applying this technology in the Heavy Duty / Commercial Vehicle segment is rising, especially where pure battery electric technology might not be able to fulfill the specific requirements of enabling long distance electric driving in combination with short fueling or charging time. As – in contrast to battery technology – fuel cells do not store, but generate electricity on-board, they enable a decoupling of vehicle weight from electric driving range which is why the heavy duty fuel cell segment sees a lot of traction.

What is required to achieve market penetration of this technology? The answer is clear: system durability has to be enhanced, while cost must come down to make the technology also economically attractive.

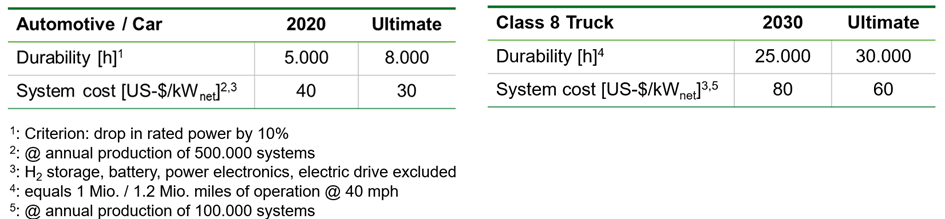

The US Department of Energy has set targets for both to enable streamlining of development activities to achieve the ultimate goals. The table shows these targets for passenger cars and Class 8 trucks.

Realizing economies of scale and reduction of catalyst cost are major levers to achieve the cost targets. One challenge is that lower platinum loadings might make the stack more vulnerable. As the lifetime of the systems need to be enhanced in parallel, degradation rates must significantly be reduced. In addition to optimizing of operation and regeneration strategies, degradation caused by e.g. airborne contamination must be prevented. Another strategy to reduce cost is to increase the system´s energy efficiency. As approximately 10% of the gross installed power is lost to auxiliaries, mostly to the compressor, any optimization of pressure drop inside the system will help to lower parasitic losses. This opens up the opportunity to reduce the installed gross power to reach the rated net power. It will also help to reduce noises from the compressor – as no internal combustion engine will cover noises from auxiliaries which requires efficient silencers inside the system. As with pressure drop optimization, this can best be achieved not by optimizing individual components, but by considering and optimizing the system performance in a holistic approach.

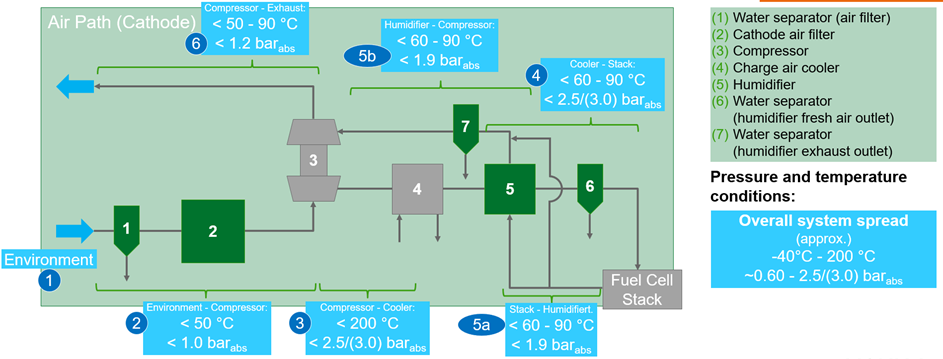

Fuel cells generate electricity in a catalyzed, electrochemical reaction between hydrogen and oxygen. While hydrogen is delivered from on-board pressure tanks, oxygen is taken from compressed ambient air. As heat is also generated by the reaction, a cooling loop is also required.

Comparing the typical pressure and temperature levels in a 100 kW automotive fuel cell system, it becomes apparent that these are similar to the levels in internal combustion engine air inlets.

To reach cost efficiency, the transfer existing technology from internal combustion engine air management to the cathode air inlet path is beneficial. Furthermore, as the fuel cell exhaust consists mostly of oxygen-depleted, hot air at high humidity, plastic technology can be applied which also offers cost- and weight-saving potentials.

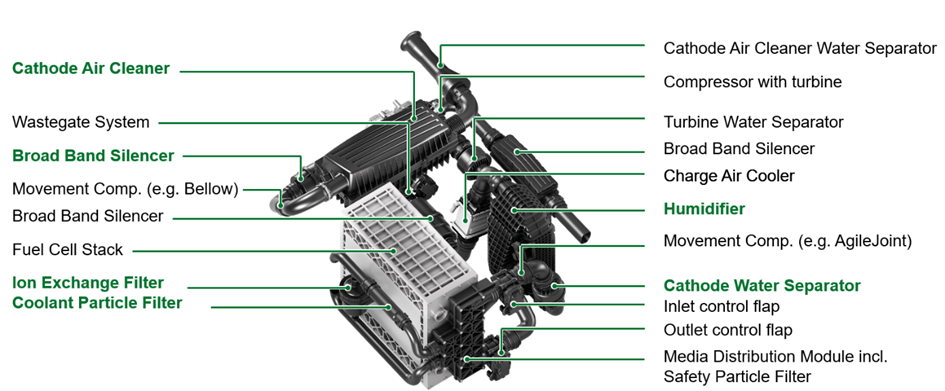

This demonstrator model shows the cathode air inlet and exhaust system as well as components for the cooling loop built around an 85 kWnet fuel cell stack. The anode loop is not shown.

The function of the cathode inlet path is to deliver clean, humid air to the fuel cell stack at the right temperature and pressure. In a first step, airborne contamination must be removed by a filter. For efficient protection, an understanding is necessary on what are the most critical contaminants. Based on lab tests and field experience, it is commonly accepted that sulfur- and nitrogen-containing gases are critical. The degree of a partial regeneration in case of NOx contamination is higher than e.g. for Ammonia, and SO2 is acting irreversibly on the catalyst in even very low concentrations. The poisoning of the catalyst results in loss of ESCA over time. In addition, Ammonia can also react with the membrane material, increasing the membrane´s internal resistivity. Whereas particles can be separated with fibrous filter media, removal of the gases requires adsorber materials.

Standard adsorber materials are not efficient in capturing the polar target gases. Here, activated carbons with acidic or basic impregnations can be used which will capture gases exposing opposite polarity by chemisorption.

There is no adsorber material available which will capture all harmful gases alike. In consequence, different carbons must be used to achieve overall protection. This might require a multilayer-design, with a tailored sequence of carbons. As the adsorber materials all have a specific capacity for the target gases, it is essential to know their typical concentrations in real-life application for a projected service life. Applying too much of the carbons will increase pressure drop and cost which is both contradicting the overall system design cost targets. Applying too little will lead to enhanced system degradation rates, lowering the targeted system durability. Besides averaged gas concentration levels, peak concentrations must also be dealt with by a filter solution.

While it is essential for high stack efficiency to deliver cathode air with high humidity, liquid water has to be avoided in the cathode air system. In the inlet stream, water separators might be placed in different positions, all with different functions. Axial cyclones can be applied to separate the water from the air stream. They combine sufficient separation efficiency for larger droplets with a low pressure drop. The presence of liquid water can lead to blocking the air stream through the filter, flooding of the stack, and blocking the pores inside the gas diffusion layer. All this will lead to oxygen starvation inside the stack.

While liquid air must be removed from the air stream, cathode air entering the stack must contain sufficient humidity to prevent the drying of the stack membranes as this would reduce the proton transport efficiency. Most systems use the water produced by the fuel cell reaction to humidify the cathode inlet air. While internal humidification inside the stack is possible, most systems use an external gas-to-gas humidifier. As the pressure of the “dry” cathode air in the inlet stream is higher than in the exhaust stream, the water must be transported against a macroscopic pressure gradient. This is achieved by applying membrane technology. The membranes must be gas-tight, but permeable for water, e.g. through a solution-diffusion mechanism. Either flat-sheet or hollow-fiber membranes can be used. Current research hints at a higher efficiency and thus better packaging for flat-sheet membranes.

Noises in the cathode air systems must be dampened by silencers. Here, broad band silencers can be applied which can dampen orifice noises, flow noises through ducts and humidifier, and compressor noises. When designing a silencer, the target is often set to reduce the noise by 20 dB. Reflective broad band silencers can be used, also with additional absorber foams.

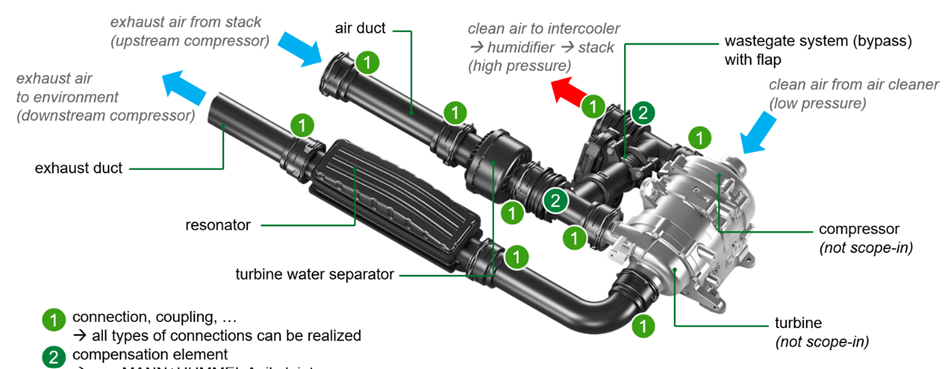

On the exhaust side, one important component is the turbine water separator. The use of a turbine can reduce the energy consumption of the compressor if the remaining over-pressure inside the exhaust stream is used to drive a connected turbine. The turbine blades must be protected from impact of large water droplets or even ice crystals to prevent mechanical damage. Axial cyclone water separators can also be used here. Integration of a water reservoir and a draining mechanism is beneficial.

A waste gate system is also integrated to shut off the air stream to the turbine to prevent harmful pressure pulses in case that the stack is shutting down fast.

The ducting can be made out of Polypropylene ducts with appropriate means for movement compensation as the exhaust gas temperature typically does not exceed 100°C.

A multi-chamber broad band silencer can be used in the exhaust path as it can also operate in the presence of water.

Through the consequent transfer of experience, products and processes from air management for internal combustion engines, entering fuel cell technology becomes possible as competences and assets can be re-used. Another way to save tooling cost and to speed up (sample) supplies is the market product approach. In this, typical technological requirements are classified into a small number of requirement sets, and standard components fulfilling these are developed. These can be applied into different systems by offering flexibility in mounting. First products developed after this concept like Cathode Air Filters and Ion Exchange Filters are already used in series application, e.g. for fuel cell busses proving that the approach is what the industry needs at this stage.

Statement: “At MANN+HUMMEL, we believe that fuel cell technology will be an important contributor to decarbonization of the transport sector, especially in the Commercial Vehicle segment. Our mission is to enhance system lifetime through innovative filtration and separation systems”

Latest News