Using epoxy SMC materials for future battery housings. An appealing alternative

A real-life case-study

In recent years, we have experienced a drastic increase in demand for electric vehicles. Since metal processing is state-of-the-art within TIER 1 suppliers and OEMs in the automotive industry since decades, metals have become the most used material in today’s first-generation battery enclosures for electric vehicles (EV). As we approach the second and third generation of battery packs, the competition is ongoing to find the best material that enables the development of more sustainable solutions without compromising on safety, cost and vehicle integration.

Novel SMC-based electric vehicle battery concept

In a lighthouse project Evonik has made a significant contribution to this material competition with a joint development project that showcases the benefits of a composite-based multi-material battery housing. The Sheet moulding Compound Composite (SMC) is based on Evonik’s newly developed Epoxy-Curing-Agent VESTALITE® S.

The innovative curing agent is specially designed for high- performance epoxy SMC applications and is the perfect choice to meet the multiple requirements and demands of the next generation high voltage EV battery housings.

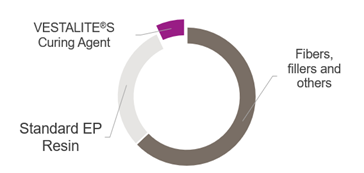

Even though the amine-based curing agent makes up only a small fraction of the whole formulation, it is the addition of VESTALITE® S that provides the differentiating factor for the overall performance of epoxy SMC materials and contributes a variety of benefits.

Cross Company case-study demonstrates the benefits of a modular multi-material battery enclosure

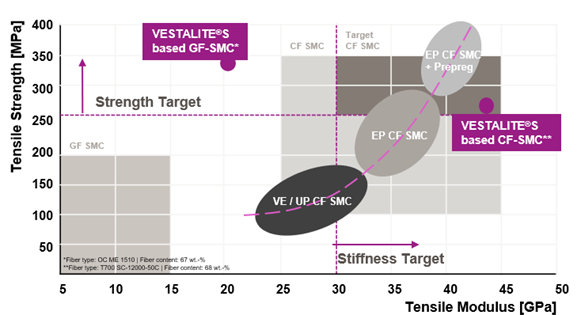

Using epoxies in SMCs leads to an increase of mechanical performance with glass-fibre and carbon-fibre-reinforcements compared to existing state-of-the-art materials. However, proving both the usability, and benefits of using an epoxy SMC material for future battery housings required the demonstration of real-life case-study.

| Figure 2 – Mechanical properties of Vestalite S based GF- and CF-SMC materials |

In a joint development project including multiple partners along the automotive battery value and competence chain, Evonik, Vestaro, Forward Engineering, LION Smart and Lorenz Kunststofftechnik teamed up to create a holistic virtual development process for a high voltage battery system which delivered a safe, lightweight, and most importantly cost-effective alternative to the current metal-based solutions that are in use.

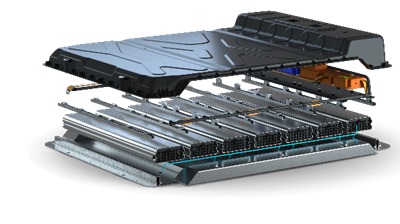

| Figure 3 – Enlarged view of the developed concept |

The central element of the new concept is the glass fibre (GF) EP -SMC cover. The novel EP-SMC formulation enables a much higher mechanical performance compared to existing polyester SMC materials, while still maintaining excellent fibre flow in a repeatable moulding process. These properties in combination with the innovative SMC design allow an integral, but scalable layout leading to an increase in overall stability as well as the individual parts of the battery housing

Since the cover helps to increase the overall stability and absorb loads during operation and crash situations, the bottom construction is designed to be as simple and cost efficient as possible. It consists of an aluminium bottom plate, extruded aluminium cross-members and extruded aluminium deformation elements.

“Battery modules and their housing has become a key area for improving the performance, efficiency and affordability of modern electric vehicles,” said Dr. Leif Ickert, Marketing Manager Composites and Adhesives, Evonik Operations GmbH & Managing Director, Vestaro GmbH. “Composite technologies provide strength and versatility, so offer a very promising solution for future battery system concepts. Our new glass fibre-reinforced SMC delivers the performance and economic benefits the automotive industry requires to push ahead with the next generation of sustainable e-mobility concepts.”

Battery performance impresses through increased safety, better insulation and faster curing times

Forward Engineering’s Computer Aided Engineering (CAE) department validated the virtual concept by means of structural and safety relevant finite element simulations. Forward Engineering evaluated the overall stiffnesses in bending and torsion, the side pole impact as well as the short time pressure resistance in case of any thermal runaway. Additionally, a 2D thermal simulation of the whole battery pack was carried out to demonstrate the insulating benefits of a SMC cover, besides the impressive mechanical performance.

The processability of the cover was also evaluated with real life production-trials of a complex hardware demonstrator. At these trials, curing times of < 5 minutes could be verified under serial production conditions.

Cost efficiency through scalable tooling

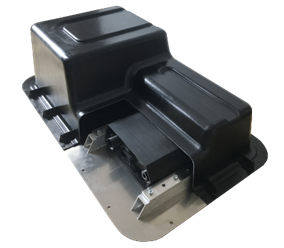

The concept is demonstrating how a multi-material-approach using a novel epoxy SMC cover can offer more sustainable solutions for high voltage battery housings for next generation EVs. In terms of cost effectiveness and scalability three different energy configurations were designed, surpassing the best battery enclosures available today in terms of energy density, safety and costs. With overall weights of 412kg (65kWh), 528kg (85kWh) and 790kg for the extreme 800V / 120kWh configuration, the new concepts developed by Evonik and its partners offer an appealing alternative for the design of high voltage battery enclosures to the automotive industry.

New approach also reduces the battery housing weight by up to 10%

In terms of safety, the new EP SMC enclosures can resist (up to three times) higher forces than the current legislative impact force requirements without causing any intrusion to the battery modules, achieve the stiffness of metal references, while also reducing the weight compared to the current state-of-the-art SMC materials by up to 10%.

The chosen cover configuration can sustain a heat treatment of 800°C for ten minutes without any burn through and can protect the surrounding materials from reaching temperatures above 300°C, due to its excellent thermal insulation. These insulation properties are also beneficial for improving battery life and battery performance under normal use as well as in extreme climate conditions.

“Working with our partners, our modular-multi-material approach for a new battery enclosure features an epoxy-based SMC which provides the high-performance and safety needed, but with a reduction in the overall battery housing weight of around 10%!” Philipp Taschner, Project Engineer Lightweight Composites, Vestaro GmbH.

“Composite technologies offer a very promising solution for future battery system concepts. Glass fiber-reinforced SMCs can provide the battery performance and economic benefits the industry requires to push ahead with the next generation of electric vehicles.” Christian Schmidt, Head of Evonik Crosslinkers Business Line, Evonik Operations GmbH & Managing Director, Vestaro GmbH. “Composite technologies provide strength and versatility, so offer a very promising solution for future battery system concepts. Our new glass fiber-reinforced SMC delivers”

Dr.-Ing. Leif Ickert Marketing Manager Composites and Adhesives, Evonik Operations GmbH & Managing Director, Vestaro GmbH

Dipl.-Ing. Philipp Taschner, Project Engineer Lightweight Composites, Vestaro GmbH