The change to electric powertrains and the increasing importance of autonomous driving imply a variety of new challenges. Thermal management or rather thermal connectivity and cooling of electrical components have an important role to play. While there is a large number of Thermal Interface Materials, the most common solution for the automotive sector are the Gap Filler Liquids (GFL) and the Soft Therm Pads, both of which can be individually customized.

According to the latest calculations by the Federal Ministry of Environment, Germany will significantly miss the self-imposed climate target of reducing CO2 emissions by more than 40% by 2020. In contrast to the trend of other sectors, greenhouse gas emissions from the transport sector recorded a slight increase compared to the referenced year 1990 and are responsible for one fifth of Germany’s total emissions. Improved vehicle efficiency could not compensate conflictual factors such as increasing traffic and engine performance. The Federal Government’s new climate protection plan envisages a 40-42% reduction in greenhouse gas for the transport sector by 2030, just a small component to meet the 2 ° C target of the Paris climate agreement. Alternative drive systems are essential in order to meet the target of 95 g CO2/km on average for cars. If these values are exceeded, car manufacturers face massive fines. This pricing mechanism has a positive impact on low-emission cars. A global rethink has to take place in the automotive industry.

Thermal Interface Materials

According to forecasts by leading German automobile manufacturers, all top sellers will also be available as an electric car by 2030 at the latest, an extremely ambitious goal. Aspects like a continuous increasing power density or higher heat flow per area (W/m2) and “high power charging” leads to increased component temperature and consequently to a reduced lifetime in the application. Efficient thermal cooling of electrical components by connecting of the heat source to heat sink, while at the same time having an electrically insulating effect, is therefore a prerequisite for the high-quality standards from the automotive sector. This connection and the levelling of appropriate component tolerances, gaps or air inclusions can be realized individually by the wide range of Thermal Interface Materials, depending on the requirements for thermal conductivity (W/mK) and desired temperature difference ∆T.

Thermal Management for e-mobility

The change to electric drive systems as well as the increasing importance of autonomous driving imply completely new applications and challenges in the field of “Thermal Management.” The functional relationship between the operating temperature of a battery stack and its maximum achievable number of cycles has been sufficiently proven, which can be quantified extremely precisely by the following rule of thumb:

“A reduction in operating temperature by 10°C doubles the lifetime of the battery cells”

The net reach of an electric car is also noticeably dependent on the operating temperature of the battery and thus also indirectly on the present thermal cooling. In addition to the concept for thermal connectivity of the energy source, the “car of tomorrow” also requires solutions for electrical components in the areas of LED, sensor technology, on-board network and inverter, one of the core elements of the electric powertrain.

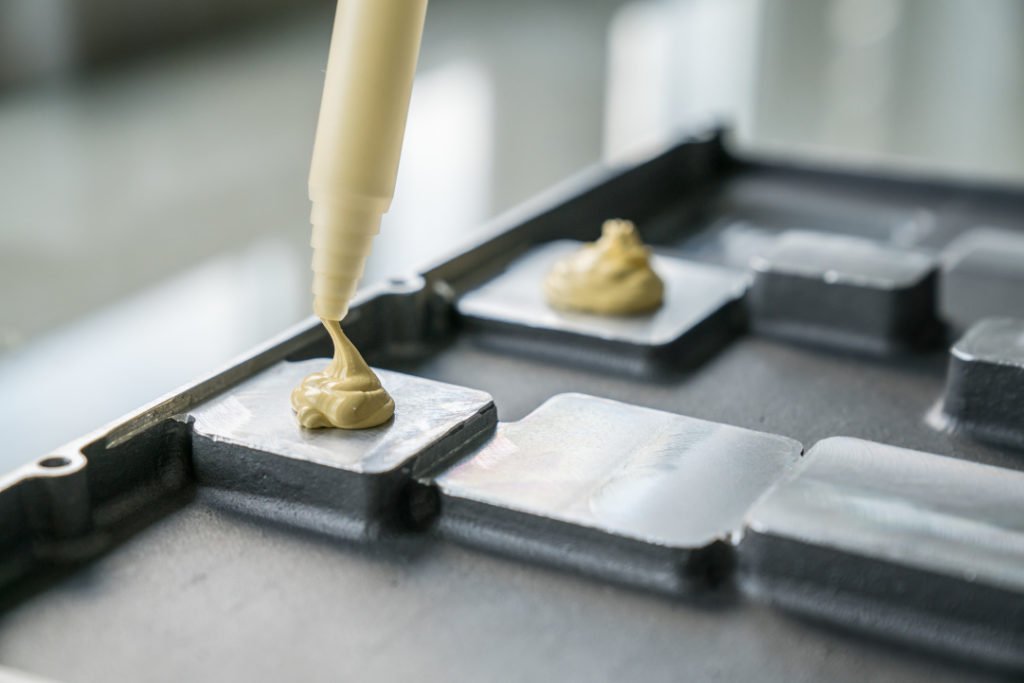

Gap Filler Liquids

For high volumes in particular, two-component GFL are an efficient and cost-oriented solution. For this purpose, the two components of the ceramic filled silicone elastomers are blended by a mixing tube and can be directly applied to the component (e.g. metal housing) by a dispensing system. In the next step, the electronic components (e.g. IGBTs, capacitors, etc.) are attached under slight pressure to the still uncured mass, thus creating an even distribution of the mass and consequently a defined thickness as well as reproducible electrical and thermal parameters. The cross-linking or curing of the mass takes place under room temperature and lasts about an hour, but can be customized at the customer’s request. Primarily the GFL with lower thermal conductivity has a high self-adhesion, which can be very useful for the assembly. Nevertheless, in case of a disassembly the GFL of KERAFOL can be removed again, a property that is not always customary in the market.

Table 1: Properties of Gap Filler Liquids

| Gap Filler Liquids | |

| Basic Material | Silicone |

| Thermal Conductivity (W/mK) | 1,8 – 4,5 |

| Breakdown Voltage (kV/mm) | 12 – 20 |

| Viscosity (Pas) | 45 – 90 |

| Application Temperature (°C) | -40 up to +200 |

| Hardness (Shore 00) | 45 – 70 |

Compared to systems based on polyurethane or epoxy, silicon-containing GFL can absorb and compensate vibrations much better, an effect that is favoured by the high softness of the GFL. In addition, the low viscosity of the GFL allows for a simple workability and has a gentle effect on the dispensing system, a thesis that has been confirmed by leading plant manufacturers such as ViscoTec, bdtronic or Scheugenpflug.

Soft Therm Gap Pads

For many thermal connections in the field of e-mobility, classic thermal conducting tapes and pads are still “state of the art.” Especially cross-linked silicone-based elastomers, better known as Soft Therm Gap Pads, can play a crucial role in thermal cooling (power range up to 6 W/mK) of electronic components due to their variety of specifically adjustable properties.

Table 2: Properties of Softtherm Pads

| Soft Therm Gap Pads | |

| Basic Material | Silicone |

| Thermal Conductivity (W/mK) | 1,0 – 6,0 |

| Breakdown Voltage (kV/mm) | 2 – 16 |

| Compression (%) | up to 40 |

| Application Temperature (°C) | -60 up to +250 |

| Hardness (Shore 00) | 10 – 75 |

Due to the high flexibility and enormous mechanical resistance of the Soft Therm Pads, large gap dimensions as well as high component tolerances can be compensated. In addition to individual solutions, such as one-sided adhesive coating for component fixation or fibreglass reinforcement to increase mechanical stability, two-layer films (required by specific regulations) can also be of great added value to the customer. KERAFOL is meeting these customer-specific requirements for many years and finds the right solution for every application, regardless of which of the “Thermal Interface Materials” is the best solution from a technical and monetary point of view.