Testing & Knowledge instead of Trial & Error

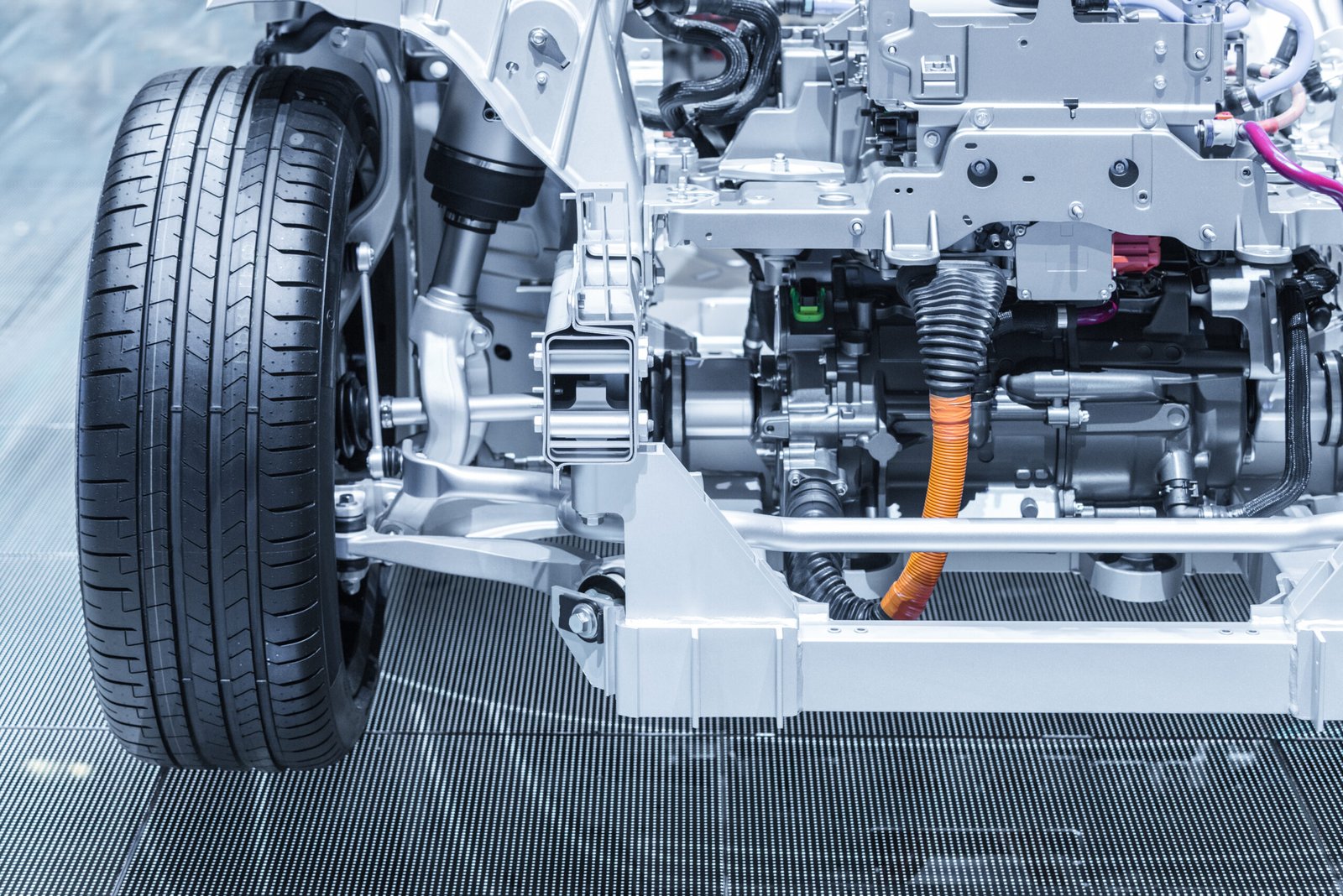

The automotive industry remains in a state of continuous evolution, battery-powered and semi-autonomous vehicles are on the rise. This increases the responsibility of vehicle manufacturers and suppliers. New testing technologies, new test procedures and new test standards are required to ensure that Li-ion batteries will provide even more power, have a longer service life and allow for longer ranges in the future. Weiss Technik makes an important contribution to this. As the global market leader for environmental simulation and a long-standing partner of the automotive industry, Weiss Technik enables and secures tomorrow’s mobility.

The enthusiasm for automotive solutions is a tradition here. For more than 15 years, the German company has been developing sophisticated testing technologies for OEMs, component suppliers and test institutes. “The automotive sector is of great importance to us. On the one hand, because its dynamics challenge our developers anew day after day. On the other hand, because it is a gigantic national and international market which we serve well and gladly,” explains Peter Kuisle, Managing Director Sales and Service of the Environmental Simulation business unit.

The company’s product range is extremely versatile and ranges from compact temperature test cabinets to large-volume climatic test chambers and test benches for complete vehicles. With this versatility, the company also scored points with the FEV Group. The internationally successful development service provider commissioned Weiss Technik to equip the currently largest EV battery testing center worldwide. For this purpose, Weiss Technik planned and built more than 60 test facilities within only 18 months. These were successively put into operation so that they could already be used during the construction phase of the test center.

In addition to numerous temperature and climate test cabinets and chambers, these include salt spray systems, dust and vacuum test chambers and a 350 kN vibration test chamber. The test systems were connected to a central refrigeration unit and integrated into FEV’s control system.

Li-ion battery testing technologies

Weiss Technik has accompanied Li-ion battery testing for about 15 years with environmental simulation systems for cells, modules, battery packs, complete drive units and battery management systems (BMS). It is important to get the enormous energy density of Li-ion batteries and the associated danger of a thermal runaway technically under control. In order to protect the test material, the test facility and above all the test personnel in the best possible way, Weiss Technik has therefore developed a hazard-level modular system which defines suitable measures for each danger level and specifies ATEX-compliant explosion protection measures.

EV battery testing technology

EV battery testing requires knowledge of all relevant standards and how they can be safely implemented in test solutions. In addition to the higher-level automotive standard LV124, UN38.3 and OEM-specific standards play an important role here. The company offers suitable standard products for many testing requirements. In addition, the company realizes customised planned and executed special solutions, for example with shaft feedthroughs, energized test specimens, racks for efficient test specimen handling or safety devices.

Especially in the field of special constructions, the Company enjoys an excellent reputation in the industry. Recently, the company was also able to support the development of standards at an EU research center in Petten, Netherlands. Here, an explosion-proof test stand for ATEX Zone 1 was developed for the world’s first testing facility for energized Li-Ion battery testing with CT images, which is secured up to Hazard Level 6. Here, energized battery modules are tested under various climatic conditions. A computer tomograph illuminates the test specimens mounted on a rotary table from all directions. The complete 3D data of the battery generated in this way allows conclusions to be drawn about its condition during the test.

Test systems from Weiss Technik are used in research and development to accelerate processes and simulate environmental influences. Furthermore, they are used in quality testing and quality assurance when serial defects or safety risks need to be detected.

There are almost no limits to the testing possibilities. With our testing facilities for Li-ion batteries, we are able to reproduce all the climatic conditions of the world in a test laboratory and to stress the test items in accordance with the standards. We simulate a cold start at the North Pole, a bumpy ride through the dusty desert or the city traffic of Bangkok and realize, among other things, extreme temperature changes, strong light irradiation, vibrations, dust and splash water”.

Janko Förster, Head of Marketing & Product Management at Weiss Technik

High-precision testing equipment is a prerequisite for standard-compliant and comparable tests. Because only if the required climatic parameters can be reliably reproduced at any time can the test results be meaningful and resilient. To ensure this, Weiss Technik has two of its own DaKKs calibration laboratories. These calibrate test systems, test and measuring equipment in the laboratory or at the customer’s site, depending on the requirements.

Parallel to the growing demand for electric vehicles, the market for partially and fully automated vehicles is also developing very positively. These require numerous sensors, control units and other sensitive electronic components. A malfunction or failure can easily lead to an accident. It is therefore important that these components function safely at all times and under all conditions. In order to check this for every single component, Weiss Technik offers special end-of-line test tunnels for the energized testing of electronic components.

The change in the automotive industry also leads to new inspection tasks and requirements. In many cases, the industry needs new testing facilities for this. In order that these do not fail in an economically tense situation due to short-term financial bottlenecks, Weiss Technik offers flexible solutions for payment and financing: classic purchase and leasing options as well as pay-per-use solutions. This enables companies to use the latest plant technology without affecting the cash flow.

A decisive factor for the technical and economic success of a test facility is its high operational reliability. Therefore, after-sales service also plays an important role. An efficient, area-wide service network with top-trained service technicians, high first-fix rates and a worldwide secured spare parts logistics contributes significantly to the return-on-investment of Weiss Technik test systems.