Testing Hybrid and Electric Vehicles

Electrical machines and drive systems place increasingly high demands on measurement and testing technology. Additional mobile and stationary test equipment is usually required in addition to conventional multimeters to ensure the safety of users. Functional and safety checks are absolutely essential, both on electric and hybrid vehicles and on the associated charging infrastructure.

Ensuring this is one of the tasks that GOSSEN-METRAWATT has set itself. For years, the company has been working in close cooperation with electric vehicle manufacturers and suppliers of charging infrastructure components to develop the necessary testing technology for this area and make it available to the market.

TESTING HYBRID AND ELECTRIC VEHICLES

A distinction is made between electric vehicles (EV), hybrid electric vehicles (HEV) – also called hybrid vehicles or cars – and plug-in hybrid vehicles (PHEV).

In the field of e-mobility, the potential for danger also increases with high-voltage on-board technology. Hybrid and electric vehicles integrate high-voltage systems with voltages far above 60 VDC and 30VAC. These are the limits of harmlessness for endangering human health or even life. According to VDE, an AC voltage of 50 V or a DC voltage of 120 V is already considered a life-threatening contact voltage for a healthy adult human being.

The danger when working on vehicles with high-voltage systems exists both through body flow and through electric arcs. Possible hazards can be caused on the one hand by improper electrotechnical work on the vehicle by insufficiently qualified personnel and on the other hand by technical defects on the vehicle. Priority must be given here to the hazards caused by technical defects and the diagnostic possibilities for detecting these defects.

Warning signs for working in HV area (source: archive IB-HJ)

FIVE SAFETY RULES FOR WORKING ON HIGH-VOLTAGE SYSTEMS IN VEHICLES

- De-energize

- Ignition off

- Pull the service disconnect plug

- Remove the fuse

- 2 Secure against restart

- Remove the ignition key and store in a secure location

- Disconnect the service/maintenance plug or remove the master battery switch and keep it in a safe place.

- Secure both against reactivation.

- If necessary, replace the service disconnect switch with a dummy plug

- 3 Verify absence of voltage with a 2-pole voltage tester

(in accordance with DIN EN 61243-3)

Observe the procedure specified by the manufacturer! This is important because residual charges may still be present in the high-voltage components even after the high-voltage battery has been electrically disconnected.

Checking for Absence of Voltage with a Voltage Tester (source: archive IB-HJ)

The system must be considered live until absence of voltage has been substantiated.

- 4 Ground and short circuit

Exception: If rules 1 through 3 have been reliably complied with, rules 4 and 5 can be omitted for electrical systems with nominal voltages of less than 1000 V AC or 1500 V DC.

5 Cover neighboring live components, or make them inaccessible

As opposed to reports to the contrary which can occasionally be found in the literature, this is also indispensable when working on high-voltage-systems in vehicles because:

- Under certain circumstances, the intrinsic safety of an early prototype vehicle may not yet be assured.

- The high-voltage system may be in an unknown state in the case of a vehicle which has been involved in an accident.

ELECTRICAL SAFETY REQUIREMENTS IN ACCORDANCE WITH UNECE R100

1) All active components in the passenger compartment and the trunk must fulfill protection category IPXXD, and in all other areas IPXXB.

2) All exposed, conductive parts – such as the conductive barrier and the conductive housing – must be reliably grounded in order to assure protection against electrical shock due to indirect contact, so that no dangerous potential can occur.

In this respect, the accident prevention regulations and UNECE R100 both stipulate a maximum resistance between any two touchable, conductive parts of less than 100 mΩ at 0.2 A.

3) Identification of high-voltage components with the high-voltage symbol

4) Cables for high-voltage busbars must be equipped with an orange outer jacket.

5) Relative to operating voltage, the following requirements apply to insulation resistance of the electric power train’s busbars to ground:

> 100 Ω / V for the DC busbar, if it’s electrically isolated from the AC busbar

> 100 Ω / V for the AC busbar if it’s protected by:

a) Two or more layers of solid insulation, isolating barriers or housing

b) Mechanically rugged protection devices with appropriate durability for the duration of the service life, e.g. motor housing

> 500 Ω / V for the AC busbar and any DC busbar connected to it

METRAHIT H&E DRIVE

Electric & hybrid vehicles can be tested according to UN ECE R100. The ECE R100 is the valid regulation for type tests of vehicles with high voltage systems for Europe and countries which have joined this regulation (all non-European successor states of the former Soviet Union, the USA, Canada and Israel).

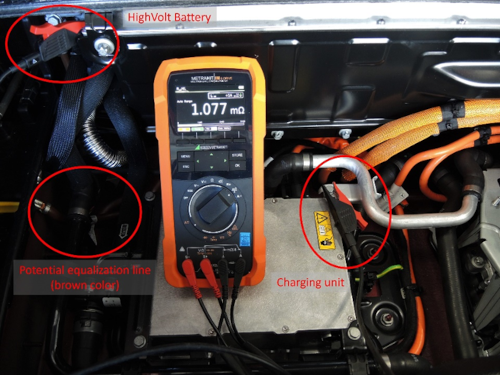

Accident prevention regulations and UNECE R100 require that the ground connection of electrical components on high-voltage systems be tested to at least with 200 mA. Vehicle manufacturers sometimes specify a 1 A measuring current.

The performance features of the METRAHIT H&E CAR with 200mA or 1A test current, an insulation test with up to 500V as well as the high-precision 4-wire measurement (Kelvin measurement) exactly meet the requirements for these demanding test tasks.

Potential equalization test between charger and HV-Battery with METRAHIT IM E-Drive

TESTING OF E-CHARGING STATIONS

The power supply device for the electric vehicle is called an e-charging station. It is a piece of equipment intended for charging electric vehicles in accordance with IEC 61851, which includes as essential elements the plug device, a line protection device, a residual current device (RCD), a circuit breaker and a safety communication device (PWM). Depending on the place of use, other functional units such as mains connection and metering may also be added.

The electrical safety of e-charging stations must be met in public and commercial areas under normal conditions, as well as under various climatic conditions, with particular attention to foreseeable misuse and abuse in the event of vandalism. However, electric vehicle charging requires lay-operated equipment for which special measures must be taken to control specific hazards.

Electrical safety is defined in the following standards for example in Germany from the field of electrical installation for protection against electric shock

- DIN EN 61140 (VDE 0140-1):2007-03, Protection against electric shock

- DIN IEC/TS 60479-1 (VDE 0140-479-1):2007-05, Effects of electric current on humans and farm animals-

- DIN VDE 0100-540 (VDE 0100-540):2007-06, Erection of low-voltage installations – Part 5-54

- DIN VDE 0100-410 (VDE 0100-410):2007-06, Erection of low-voltage installations – Part 4-41-

- DIN VDE 0100-530 (VDE 0100-530) Erection of low-voltage installations – Part 530

- DIN VDE 0100-722 (VDE 0100-722) Erection of low-voltage systems – Part 7-722 – Power supply for electric vehicles,

- DIN VDE 0100-600 (VDE 0100-600) Erection of low voltage installations – Part 6:

PROFITTEST MXTRA

With the profitest MTECH / MXTRA all safety-relevant electrical tests can be carried out and documented in accordance with DIN VDE 0100-600 (IEC 60364-6) and DIN VDE 0105-100. Furthermore, in connection with the GOSSEN METRAWATT test box, it is possible to map and also document the operating states according to IEC 61851 via an internal test sequence in the PROFITEST.

According to IEC 61851-1, a distinction is made between 4 charging modes (modes 1-4). Charging mode 1-3 is line-based charging with “on-board charger”, i.e. the charger is located in the vehicle, and charging mode 4 for DC charging with “off-board charger”.

Mode 1: AC charging at standard socket with up to 16 A; 250 V (AC) single-phase or 480 V (AC) three-phase;

Mode 2: AC charging at standard socket with up to 32 A; 250 V (AC) single-phase or 480 V (AC) three-phase;

Mode 3: AC charging at special charging stations with up to 63 A; 250 V (AC) single-phase or 480 V (AC) three-phase;

Mode 4 DC charging at special charging stations; mostly fast charging stations;

Test of Charging Infrastructure with PROFITEST MXTRA

Testing of e-charging cables

In order to be able to test the effectiveness of protective measures on e-charging cables for electric and hybrid vehicles, simulations of fault cases are prescribed in accordance with DIN VDE 0701-0702. Furthermore, fault cases are required by the manufacturer specifications for testing charging cables.

The PROFITEST E-Mobility is an adapter for standard-compliant testing of 1- and 3-phase charging cables mode 2 and 3 by simulating fault cases according to DIN VDE 0701-0702 as well as manufacturer specifications. With this accessory, which is perfectly tailored to the requirements. By means of a simulation of the fault cases interruption, conductor exchange and PE to phase, a function or tripping test can be carried out. The protective conductor current is measured in conjunction with the clamp-on current transformer, which is available as an accessory.

In conjunction with the PROFITEST MXTRA / MTECH+, the following measures can be carried out :

– Measurement of protective conductor and insulation resistance according to DIN VDE 0701-0702

– Tripping test with rated residual current and measurement of tripping time

– Guided test sequence according to DIN VDE 0701-0702

– Simulation of vehicle condition according to EN 61851-1/VDE 0122-1

– Testing of resistance coding for vehicle coupling and connector according to EN 61851-1/VDE 0122-1

– Evaluation and logging of the individual test steps

Dipl.-Ing. Klaus Leibold Product Manager Gossen Metrawatt GmbH