Dr. Horst Ammon

The right temperature control is driving electromobility forward worldwide

From the extreme heat of the Sahara to the freezing cold of Siberia – so that battery electric vehicles can be on the road all over the world, the thermal influences on the components and the effect on functionality are thoroughly tested under a wide range of climatic conditions. But valid results are only possible if test benches correctly and reliably display the resulting temperature conditions.

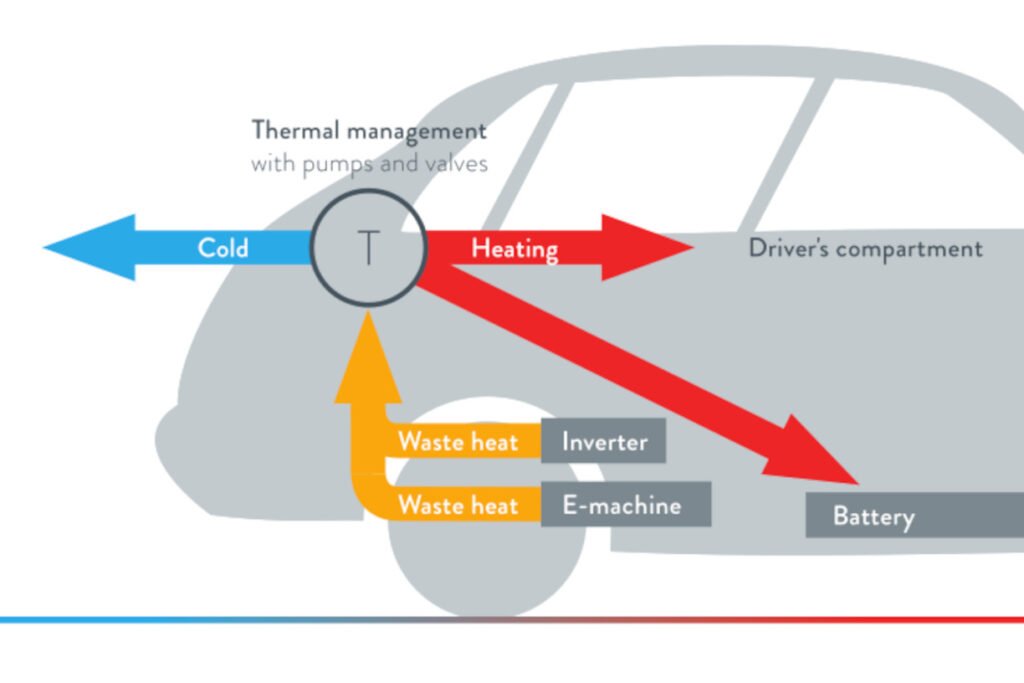

Importance of thermal management in electromobility

The most important point in electromobility is the range of the vehicle. This can be achieved through more powerful batteries and improved energy management on the consumer side. The temperature is of central importance in several respects: The ambient temperature influences the provision of electrical energy in the batteries, the efficiency of the electrical consumers and the well-being of the passengers. If the batteries are too cold or too hot, they deliver less energy. If electrical consumers run at a lower efficiency, they produce more waste heat. If passenger compartments are heated electrically, waste heat from other consumers is lost unused and precious electrical energy for propulsion is lost.

In order to use the individual electrical consumers in an energy-optimized manner, an intelligent temperature control concept is required. For this purpose, several temperature control circuits are implemented in a vehicle to provide different temperature levels. Energy is transferred via heat exchangers and heat pumps, which are then used to heat the passenger compartment, for example. Energy-efficient pumps adjust the volume flow of the temperature control media so that, together with the adjustable temperature difference, the amount of heat transferred can be controlled very precisely. Since batteries currently account for up to 40 percent of the cost of an electric vehicle, their temperature-optimized operation is particularly important.

Importance of the volume flow for reproducible test processes

The components in electric vehicles are constantly being improved. In order to know how they react to heat and to achieve high quality in production, validated test procedures are required. Often, even single-unit testing takes place in specially adapted test benches. Climatic chambers simulate the ambient temperature, while process thermostats take over the temperature control of the coolant for the simulation of the cooling circuits in the vehicle. Temperature sensors at the test item inlet and outlet determine the temperature difference. Together with the measured volume flow and the heat capacity of the temperature control medium, the amount of heat transferred can be precisely controlled and determined. This means that a validated test process can be defined.

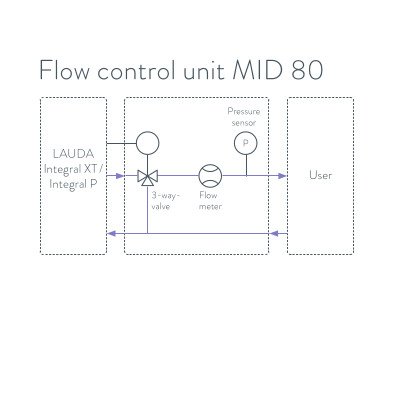

Similar to vehicles with internal combustion engines, water-glycol-based coolants are frequently used in electric vehicles. Since high voltages of currently up to 800 V are used in electric cars, the conductivity of these coolants must be very low to prevent voltage breakdown. Nevertheless, magnetic inductive volume flow measurement methods are applicable. On this basis, LAUDA, world market leader for temperature control devices from Germany, has developed a new flow control unit that measures the volume flow and controls it via the controllable pump of the Integral XT process thermostat up to a usable 70 L/min. If required, a bypass and a control valve also allow the necessary precision at very low volume flows down to 2 L/min. Process thermostats are used more frequently in such test processes because they allow precise control of the temperature. The Integral XT line of instruments operates on the flow-through principle with cold oil superimposed on a small active volume. This allows it to realize very dynamic temperature changes.

With an Integral XT of the latest generation, it is now possible to provide all data for energy balances of the test process by recording two external temperature values and an exact volume flow. For integration into a modern IT environment, for example in the context of Industry 4.0, the Integral XT process thermostats offer modules with interfaces such as Profibus, RS 232/485, Kontakt Namur, Kontakt Sub-D, EtherCAT, a second external Pt 100, analog or Ethernet TCP/IP. Significantly improved maximum flow rates for Integral XT unit types of 65 or 120 L/min extend the range of use for controlling heat transfer from temperature difference and volume flow. However, the viscosity of the temperature control medium and thus the resistance in the hydraulic structure must also be taken into account in this context. At lower temperatures, the viscosity increases disproportionately. This increases the resistance in the lines and reduces the maximum volume flow.

Measurement accuracy and calibration of the volumetric flow meter for reproducible test processes

To ensure very good measuring accuracy, each volume flow controller is calibrated individually. The geometry of the supply line and the discharge line is specified for a certain length. Furthermore, the cross-sections of the pipes are specified for certain volume flow ranges in order to be able to record the corresponding flow velocities. The accuracy of the volumetric flow meter is given as a percentage deviation from the measured value. This means that within the measuring range, the accuracy is stable at higher flow rates, while it decreases at lower or very low rates. If certain flow rates are of interest, volumetric flow meters can be calibrated to these points. In principle, calibratability is a necessary prerequisite for obtaining reproducible results over longer periods of time.

Pushing the limits of what is physically possible with superior refrigeration technology

In order to be able to reproduce the earth’s climatic zones as far as possible with inexpensive coolants, automotive applications use water/glycol mixtures that can be used in practice for low temperatures of -40°C, depending on the mixing ratio. If the glycol content is above 38 percent, the liquid does not develop any bursting effect when cooling below the pour point.

In practice, 50/50 mixtures of glycol and water are often used for the tests. Tempering processes down to -35 °C are physically feasible with this mixture. With a proportion of 60 percent glycol, temperatures as low as -40 °C can even be achieved. The intelligent LAUDA Smart-Cool system of the Integral process thermostats makes it possible to balance the evaporation temperature of the refrigerant in the refrigeration circuit and the liquid temperature of the coolant in the heat exchanger of the Integral XT in such a way that the coolant does not boil and the volume flow for temperature control can be maintained.

Conclusion: The range of electric vehicles can be maximized if the temperature currents in the car are intelligently controlled. LAUDA Integral process thermostats help to simulate these temperature currents in test benches, record the data precisely and control the heat exchange intelligently.

Dr. Horst Ammon, Senior product manager, LAUDA DR. R. WOBSER GMBH & CO. KG