Electric and hybrid vehicles must be designed with a holistic mindset to ensure compliance with regulations, safety and customer acceptance.

Along with the benefits provided by electric and hybrid vehicle (E&HV) technologies is a new set of challenges that need to be addressed and overcome. Because electric motors are so much quieter than their internal combustion engine (ICE) counterparts, many NVH evaluations need to be rethought. Some, like tyre and wind noise will not change, but the silence of the motor reveals noises that were previously masked by the powertrain. There are also new noise challenges introduced as the quiet electric motor is suddenly supplanted by an influx of noise from the ICE powertrain of a hybrid. And while those are new challenges, they can still be handled with more traditional methods, like noise source identification. But there is also a new range of challenges that stem from the quiet, itself.

Active sound design for interior and exterior vehicle sounds

With the new regulatory requirements in the UN Regulation 138 (UN 138) and Federal Motor Vehicle Safety Standard No. 141 (FMVSS 141) standards for Quite Road Transportation Vehicles (Electrical vehicles and Hybrid electrical vehicles), it is now necessary to ensure that these types of vehicles make sounds when running at low speeds (below 30 km/h) and reversing because of the risk that pedestrians or bicyclists cannot hear the vehicle. Therefore, all these vehicles must be equipped with an acoustic vehicle alerting system (AVAS) and undergo testing to ensure that the AVAS meets the standards.

As always, in addition to compliance with standards, AVASs must also be designed in a holistic way so that these sounds align with the branding characteristics of the specific vehicle line and ultimately curry customer acceptance or they won’t sell.

Designing sound for your vehicle

VSound is a sound generation system for vehicles. It is both an integral part of Brüel & Kjær’s NVH Simulator suite, enabling interior and exterior sounds to be evaluated while driving on actual roads, and part of the final vehicle in the sound profile created. The primary uses of VSound are to develop appropriate interior and exterior sounds for electric and other quiet vehicles, present exterior sounds of differing complexities to define production hardware requirements, design discrete sources on an internal combustion (IC) vehicle (for example, intake or exhaust systems) to create a distinctive exterior sound quality and to evaluate any potential interior or exterior vehicle sound design in the real world.

Traditionally “on-road” and “desktop” simulators have been used at the concept stage to deliver an exciting sound to enhance and compliment a new vehicle. But with the increasing market for electric and hybrid vehicles, those sounds may not just complement an existing sound, they could make up the entirety of the sound both for customer acceptance and legislated standards compliance. Using an NVH simulator in conjunction with this type of sound enhancement simplifies the process greatly. Sound can be auditioned, developed and refined in an NVH simulator, transferred to an in-car sound-generation unit for verification and final refinement using VSound, then transferred to the on-board entertainment system for production sound enhancement purposes.

One of the great challenges of the NVH development process is to ensure that customers and stakeholders in the vehicle team are involved in sound quality decision making. Interactive NVH simulators have enabled a cost-effective, customer-focused method for capturing the opinions and decision-making processes of non-NVH experts. The VSound solution enables custom sounds to be composed on a desktop simulator, which in turn allows those sounds to be evaluated while driving on the road. The sounds are created and presented to the driver in such a way that they appear totally natural and the assessor is not aware that they are synthesized. Because the subjective evaluations are performed on normal roads, key decision makers can understand and appreciate the value of the proposed sounds.

The Importance of sound quality

The term “sound quality” is generally used to describe those features of a sound that generate a positive emotional response from the driver or passenger. In fact, sound quality not only influences the way the customer reacts to the car, the car’s overall character can also be reinforced by its sound quality.

By studying independent vehicle quality survey data, the customer’s perception of sound quality can be correlated with other aspects of the vehicle’s performance. In a sample case, customers were asked to rate the performance of the car during rapid acceleration from a stop and to rate the sound of the engine/exhaust during rapid acceleration on a scale from 1 – 10 with 1 being “unacceptable” and 10 being “outstanding”. Results showed a clear correlation between a customer’s opinion of the engine sound and their perceptions of both acceleration performance and, more surprisingly, overall dynamic performance. Furthermore, by looking at the way customers describe their vehicles, there is a clear link between the performance of the vehicle and its sound.

The result of VSound

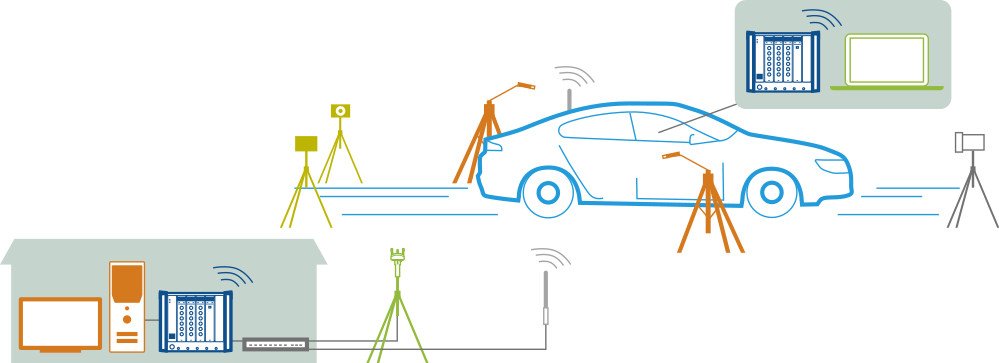

With VSound, the various vehicle parameters such as engine or motor speed, vehicle speed, gear selection, pedal position and other parameters from the CAN-bus or transducers are used to generate sound in real time, responding instantly to any changes in the vehicle inputs. Interior and exterior vehicle sounds developed in the Desktop NVH Simulator or Exterior Sound Simulator are generated by VSound hardware utilizing the same methods used on the desktop, recreating the sound in the actual vehicle as that designed on the desktop. The sounds are replayed through existing vehicle speakers, additional interior or exterior speakers or other transducers/AVASs.

Testing to ensure compliance

Pass-by noise measurement is a requirement for all automotive manufacturers as part of product certification, with measurement procedures defined in local and regional standards to ensure that noise levels are not exceeded. However, due to E&HV’s low noise levels at low speeds, it has become necessary to ensure minimum noise requirements to ensure the safety of pedestrians in traffic. This means that, in addition to the current noise level requirements for all vehicles, the new standards specifically created for E&HVs (FMVSS 141 and UN 138) cover minimum noise levels and stipulations for shifts in the sound based on changes in velocity. FMVSS 141 requires a shift in amplitude at specified frequencies and UN 138 requires a shift in the frequency.

Brüel & Kjær’s pass-by solutions provide tools for performing outdoor and indoor pass-by measurements according to the new UN and FMVSS standards as well as the standard range of international standards. PULSE™ vehicle pass-by solutions are complete data acquisition and analysis platforms, including relevant software (indoor or outdoor), LAN-XI data acquisition hardware, pass-by related accessories (such as photocells) for giving absolute position reference, a speed sensor (radar, GPS or other device) to provide continuous speed and position information, and a weather station for providing environmental parameters. The system is scalable, ranging from conformance test configurations to multi-vehicle configurations with on-board vehicle measurement channels. Single-person operation is also supported.

To ensure that measurement according to the standards is as simple as possible, a dedicated user interface has been developed for FMVSS 141 and UN 138. The interface provides a workflow from set-up, through all the different conditions and finally to the results table. After setting up the hardware according to the on-screen instructions, select the relevant standard from the dropdown list, and the user interface follows workflow based on that standard to ensure that the data will be correct and valid. The results are calculated and presented in the results table, from which reports can be easily exported to a spreadsheet.

Due to the increased demands the new standards place on the operators, the user-centric workflow reduces the process complexity (simply selecting the standard and following the built-in workflow) so that the operator can focus purely on the task of driving according to the standards. And this process concept is the same for the UN 138 frequency shift requirement and FMVSS 141 amplitude shift. For example, select UN 138 frequency shift as the standard, perform the measurements according to the built-in workflow, and the test result will perform all calculations and display the frequency shift for each speed.

The product

In the end, it is a combined development and testing effort that ensures a final product that complies with regulations, ensures the safety of the end users and those around them, and ultimately a product that customers want.