With 43% more PHEV/BEV sold in 2020 than in 2019 (ev-volume), the electrification revolution is happening. Manufacturers increase the announcement pace of new EV models introduction and the investments into electrification. The efficiency of the electrified powertrain is a cornerstone identified by all actors in the industry to enable the success of the democratization of EVs on the market. Improving efficiency has numerous benefits. It enables the increase of the range, the acceleration of the charge, the reduction of the battery size and thus, the reduction of the vehicle cost and weight. Currently, most of the efforts to enhance electrified powertrain efficiency are focused on the technology of power devices, replacing traditional MOFSET and SI IGBT with SiC and GaN power transistors as they are a lot more efficient and reduce significantly the energy switching losses. The change of paradigm is also necessary for the digital control to unleash advanced control algorithm implementation such as higher frequency control and angle-based modulation methods.

Silicon Mobility accelerates the e-mobility transition in the cleanest, safest, and smartest way thanks to its OLEA® solution. The solution is built upon a versatile hardware platform: the OLEA® T222 FPCU, a powerful chip dedicated to automotive real-time control applications. Customers have the choice to develop their control application using OLEA® COMPOSER and OLEA® LIB, an application development environment with control and algorithm library, or use OLEA® APP INVERTER, a turnkey control application software for the efficient control of inverter and electric motor.

OLEA® FPCU T-222 is a safe and real-time automotive control solution. It is the industry’s first Field Programmable Control Unit (FPCU), a unique semiconductor architecture defined as a combination of accelerated parallel processing, and hardware flexibility for critical real-time control and ASIL D level functional safety. It is designed to process critical information faster with 100% predictability and accuracy as needed by the next generation of EVs and HEVs.

OLEA T222 FPCU Block Diagram

Advanced customization

OLEA® COMPOSER

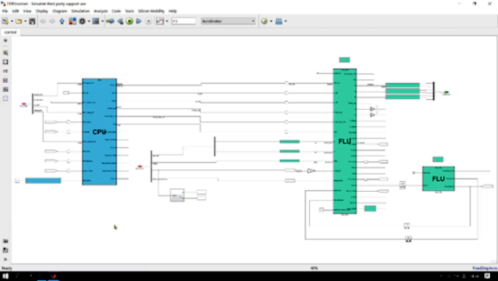

This orchestrates a wide set of industry-standard EDA tools all along the V-model design cycle and accelerates development on OLEA® FPCU. From Model-in-the-Loop (MiL) down to Hardware-in-the-Loop (HiL), developers drastically reduce development, validation, and calibration time while significantly improving performances using the Hardware/Software split provided in the framework.

With OLEA® COMPOSER, users can design from models using MATLAB/Simulink targeting directly OLEA® FPCU. Users can directly generate the SW and HW code from MATLAB and run a compilation to generate the binary code. It also allows the user to flash the binary into OLEA FPCU and run HiL simulations or directly the application on a testbench. At any time, the user can validate and calibrate the control using standard calibration tools from Vector or ETAS thanks to the ASAM standard compliancy.

OLEA COMPOSER Target Framework for MATLAB/Simulink

OLEA® LIB

is a rich collection of advanced software and automotive algorithms optimized for OLEA®️ FPCU. It is tailored for integration into electrified powertrain systems. It is packaged into complementary building blocks that offer incremental levels of performance and content based on customer and application needs. The library contents come as reference and target models for MATLAB and Simulink. Models out of OLEA®️ LIB are directly usable within OLEA®️ COMPOSER for MiL simulations and automatic code generation.

Two key benefits thrive from OLEA® LIB. The first is to offer best-in-class boost performance. Its software and algorithms have been optimized for OLEA®️ FPCU and take all the benefits of the hardware resources and accelerators available (mathematical units, DSP functions, and standard peripherals) to deliver the highest achievable performance and integration. The second benefit is the shorten development times. By using OLEA®️ LIB, developers drastically reduce the time required to develop, optimize, test, and calibrate their algorithms on OLEA®️ FPCU. Each function in the library is configurable upon multiple parameters and is fully integrated into OLEA®️ COMPOSER Target Framework.

OLEA® LIB portfolio includes OLEA® LIB MATH (mathematical functions acceleration) and OLEA® LIB ALGO (control algorithm building blocks).

OLEA® APP INVERTER

This addresses the need of EV/HEV manufacturers and automotive Tier 1s for short time-to-market solutions with a quick start into the development of applications for best-in-class control of electric powertrains.

The application is based on the OLEA® T222 FPCUs parallel architecture, which allows extremely high-performance real-time control of advanced power electronics and electric motors. It provides efficient and safe torque and speed control using Field Oriented Control (FoC) and variable Space Vector Pulse Width Modulation (SVPWM) algorithms. The modular software can be adapted to a large variety of customer applications, being it Low or High-Voltage systems, or PMSM or WRSM multi-pole/ multi-phase motor. The high controller performance supports MOSFET and IGBT power transistors and is particularly suited for the latest SiC or GaN-based inverters technology. By exploiting the programmable and parallel hardware of the OLEA® T222 FPCU chip, it allows real-time control loops and switching frequencies up to 100 kHz. The application has two independent stacks – one for control and one for functional safety – designed as AUTOSAR Complex Device Drivers. Thus, the application is ready to satisfy the increasing demands of next generations electric powertrains without software bottlenecks.

OLEA T222 FPCU-based Inverter Control Board

To support customers’ developments, the OLEA APP INVERTER platform enables a fully integrated model-based design flow along the development cycle, from Model-in-the-Loop over Hardware-in-the-Loop simulations including easy calibration and validation thanks to its native ASAM standard support.

“More EVs maker, more models, and little support to catch up. With OLEA® APP INVERTER, OEMs and Tier 1s can have a quick start to build differentiated and powerful EV/HEV systems » says Rainer Kallenbach, CEO of Silicon Mobility. “Based on a common, modular open platform, our solution may be used both as a standalone control, or to extend the capability of an existing system to make it future proof.