Revolutionizing Thermal Management in E-Mobility: High-Performance Sealing Solutions

In the ever-evolving landscape of electronic mobility (e-mobility), pursuing higher efficiency, extended battery life, and enhanced safety remains paramount. One critical factor that significantly impacts these goals is thermal management. Efficiently dissipating heat generated by electronic components in electric vehicles (EVs) and other e-mobility applications ensures optimal performance and longevity. Schlegel Electronic Materials, a pioneering company at the forefront of sealing solutions, prioritizes innovation in thermal conductivity management. Here, we investigate how these innovations revolutionize thermal management in e-mobility, bridging the gap between OEMs and vehicle manufacturing companies.

The Thermal Challenge in E-Mobility

E-mobility has ushered in an era of cleaner and more sustainable transportation. However, this transformative shift comes with a unique set of challenges. Electric vehicles rely on a myriad of electronic components such as batteries, power electronics, and electric motors, all of which generate substantial heat during operation. Managing this heat is essential to ensure the vehicle’s reliability, safety, and overall performance.

Traditional internal combustion engine vehicles dissipate excess heat through the radiator and exhaust system. In contrast, EVs must rely on alternative means to dissipate heat generated by electric components to maintain optimal operating temperatures. Vehicle components are sensitive to temperature extremes, and overheating can lead to performance degradation and even safety hazards.

A broad overview of the primary challenges include:

1. Heat Generation: EVs rely on various electronic components, including batteries, power electronics, electric motors, and charging systems, all generating heat during operation. Designers must address the challenge of efficiently dissipating this heat to prevent overheating and ensure that these components function reliably.

2. Battery Temperature Control: Lithium-ion batteries, commonly used in EVs, are sensitive to temperature extremes. Operating them at excessively high temperatures can reduce battery life, performance degradation, and safety risks such as thermal runaway. Decision-makers must implement effective thermal management strategies to maintain batteries within the optimal temperature range.

3. Energy Efficiency: Heat generation in EVs represents energy not being used to propel the vehicle. Decision-makers must balance the need for thermal management with energy efficiency, aiming to minimize energy wasted as heat while ensuring components remain within safe operating temperatures.

4. Compact Design Constraints: EVs often have limited space for thermal management components such as heat sinks and cooling systems. Decision-makers must find innovative solutions for effective thermal control without compromising vehicle design, aerodynamics, or passenger and cargo space.

5. Variability in Operating Conditions: EVs operate in diverse environmental conditions, from extreme cold to scorching heat. Decision-makers must develop thermal management systems that can adapt to these varying conditions, ensuring consistent performance and safety regardless of climate.

6. Regulatory Compliance: Regulatory requirements and safety standards often dictate acceptable operating temperatures for critical EV components. Decision-makers must ensure that their thermal management solutions meet or exceed these standards to ensure vehicle safety and compliance.

7. Cost Considerations: Developing and implementing advanced thermal management solutions can be expensive. Decision-makers must balance the need for high-performance thermal management with cost-effectiveness to ensure EVs remain competitive.

8. Materials and Insulation: Selecting materials with low thermal conductivity for insulation and seals is crucial. However, decision-makers must also consider these materials’ durability, compatibility, and environmental impact when choosing thermal management components.

9. Future Innovations: The EV industry is constantly evolving, with new technologies and materials emerging regularly. Decision-makers must stay current with the latest advancements in thermal management to remain competitive and take advantage of opportunities for improved performance and efficiency.

10. Testing and Validation: Ensuring the effectiveness of thermal management solutions requires extensive testing and validation processes. Decision-makers must allocate resources for research, development, and testing to guarantee that their chosen thermal management strategies meet the desired objectives and safety standards.

Thermal Conductivity: The Key to Efficient Heat Management

Efficient thermal management in e-mobility applications hinges on several factors, with thermal conductivity being one of the most critical. Thermal conductivity measures a material’s ability to conduct heat, and in the context of e-mobility, the lower the thermal conductivity, the better. This is because materials with low thermal conductivity act as effective insulators, reducing heat transfer from hot components to surrounding areas. As a result, they help maintain the desired operating temperatures, enhancing the overall efficiency and safety of e-mobility systems.

Schlegel Electronic Materials: Industry Resources

Schlegel Electronic Materials is a key partner in helping industry leaders address the thermal management challenges faced by e-mobility. Their innovative materials, designed with the lowest thermal conductivity in mind, have been instrumental in helping OEMs and vehicle manufacturing companies achieve their goals for improved thermal management.

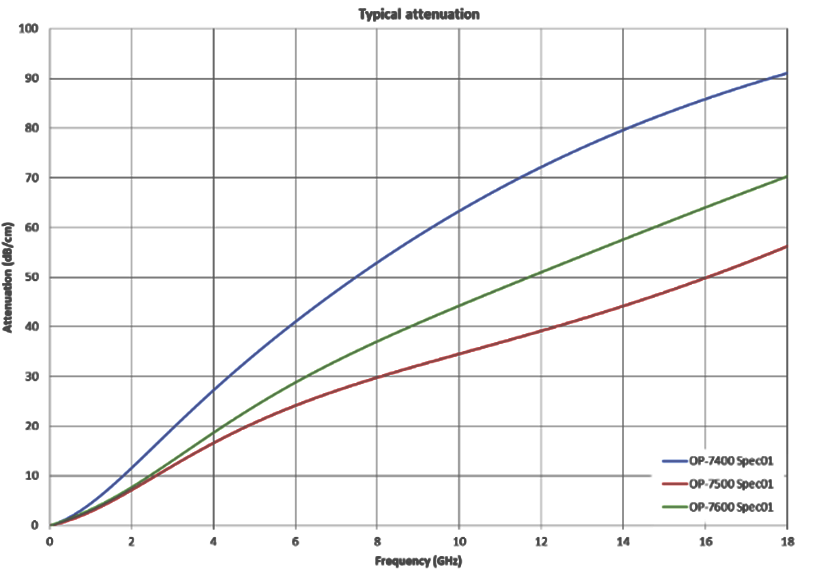

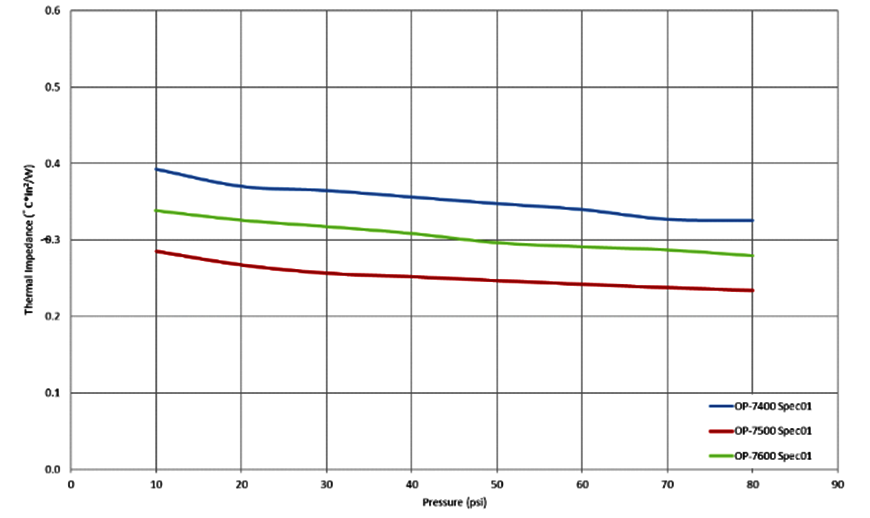

- Hybrid Thermal/EMI Absorbers: By utilizing combination thermal/EMI absorber products like Schlegel’s TIMSorb® Thermal/Absorber materials, engineers can effectively address thermal management and EMI issues. They can use these materials as thermal interfaces in critical components and metal chassis, ensuring efficient heat transfer while suppressing EMI emissions that may interfere with other vehicle electronics or external communication systems. Combination thermal/absorber materials can help designers optimize the placement of sensitive electronics and batteries without the fear of overheating, enabling more compact and efficient designs. Refer to Fig. 1 for TIMSorb’s Attenuation and Fig. 2 for the material’s Thermal Impedance.

Fig.1 Thermal impedance with 1.0 mmT vs Pressure

Figure 2

- DoubleShield Pad: When it comes to automotive electronic devices, it’s essential that grounding and shielding products can maintain their electrical performance even when subjected to mechanical or environmental stress over time. The Schlegel DoubleShield Pad is an SMT-compatible product that offers both conductivity and convenience, ensuring that electric vehicles can maintain consistent pressure and electrical contact with their battery cells. Engineers can protect sensitive and expensive electronic components using high-performance products like the Pad to ensure maximum performance. Refer to Fig. 3 for the DoubleShield demonstration.

Figure 3

- Customized Solutions: Schlegel Electronic Materials, a supplier for e-mobility applications, understands that every application is different. To meet the specific needs of each OEM, they work closely with them to develop customized sealing solutions. This level of customization ensures that the thermal management requirements are met precisely for different vehicles and electronic systems.

- Reliability and Durability: Schlegel’s sealing solutions offer low thermal conductivity and excel in reliability and durability. These materials are engineered to withstand the rigors of e-mobility, including temperature variations, vibrations, and exposure to moisture, ensuring that electronic components remain well-protected throughout the vehicle’s lifecycle.

The Impact on E-Mobility

High-performance sealing solutions have a profound impact on the e-mobility landscape:

1. Extended Battery Life: By effectively managing heat, Schlegel’s sealing solutions extend the lifespan of lithium-ion batteries in electric vehicles. Reduced heat exposure minimizes the risk of thermal runaway and degradation, resulting in longer-lasting batteries with improved overall performance.

2. Enhanced Efficiency: Improved thermal management increases energy efficiency in e-mobility applications. With less energy wasted as heat, vehicles can travel longer distances on a single charge, helping to address one of the main concerns of EV adoption—range anxiety.

3. Safety Assurance: Sealing solutions play a crucial role in ensuring the safety of e-mobility systems. By preventing overheating and thermal incidents, these materials mitigate the risk of fires or damage to sensitive electronics, bolstering the safety of the vehicle and its occupants.

In pursuing a sustainable future, e-mobility is here to stay, and efficient thermal management is crucial for its success. High-performance sealing solutions with low thermal conductivity, are a pivotal technology in this space, bridging the gap between OEMs and vehicle manufacturing companies. By enabling extended battery life, enhanced efficiency, and safety assurance, these innovations are shaping the future of e-mobility. As the industry continues to evolve, industry commitment to innovation must keep pace to unlock new possibilities for cleaner, more sustainable transportation worldwide.

Monica Monte, Technical Product Marketing Manager