PRESSURE SENSITIVE MATERIALS – APPLICATIONS AND DESIGN CONSIDERATIONS

Everyone uses pressure-sensitive materials daily, often without realizing it. For example, we all use shampoo in labeled bottles, self-adhesive stamps, and tapes. Most of us only realize if labels behave differently than expected without even trying to understand the science behind them.

In the field of transportation and e-mobility specifically, high performing pressure-sensitive materials are used in various applications. This article will discuss pressure-sensitive solutions for EVs including batteries, labelling for components, and the different types of pressure-sensitive adhesives needed for various substrates and films.

EV BATTERY SOLUTIONS

The technologies and manufacturing processes are steadily evolving for EV batteries, creating needs and opportunities for pressure-sensitive materials with increasing technical requirements. We explore some of these applications below:

Figure 1: self adhesive solutions inside an EV Battery

Cell wrapping film

Lithium-ion batteries are used in electric vehicles, consisting of battery cells assembled into modules, which are finally put together in packs. Each battery cell needs electrical insulation and mechanical protection around the entire length. The most effective way to achieve secure protection is using a self-adhesive film, which can be applied precisely and cleanly, offering a broad process window. Next to the electrical insulation and puncture resistance, essential features are good adhesion to aluminum and aging resistance.

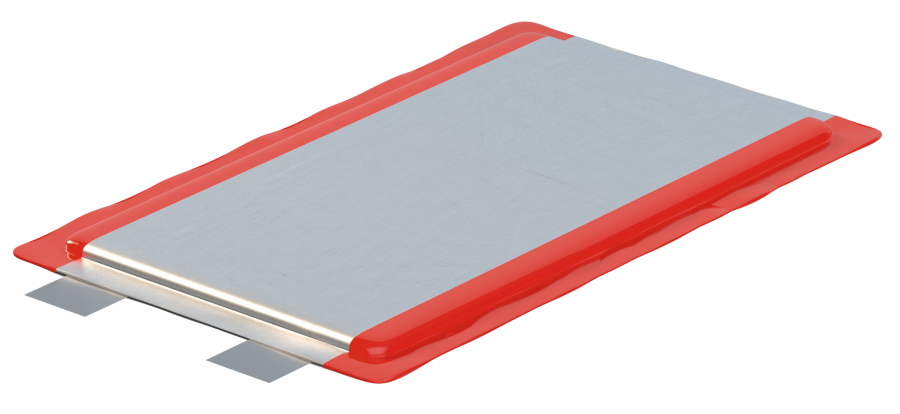

Figure 2: cell wrapping film

Pouch cell edge protection film

Insulating films with low stiffness and a highly cohesive adhesive are used to provide insulation and abrasion protection for the edge of the pouch cell. This is to prevent mechanical damage to the edge of the pouch cell during long-term operation.

Figure 3: Pouch cell protection

Tapes for multiple bonding applications

Multiple tapes are used for mounting insulating materials (aerogel, silicone foam pad, mica sheet) between cells or inside battery packs. Heating and insulation films and thermal interface materials are bonded to battery or battery components, while FPCs are attached inside the battery, withstanding various severe working conditions over the battery’s lifetime.

EV LABELING SOLUTIONS

Whereas the previously described applications are somewhat hidden high-performance materials, printed labels are used to identify components or the final vehicle. Digital product passports are being introduced to bring transparency to manufacturers and consumers via a digital identity, provided as a QR code or an embedded RFID tag. Information about the battery, starting from the raw materials and production, the usage and maintenance, to repurposing and end-of-life, can be stored and retrieved by mechanics and consumers.

Warning and handling text is often printed using UV-cured flexo inks, or digital printing methods, for example, UV inkjet technology. Serial numbers and variable information, including QR codes, are added on demand with thermal transfer printers or laser markers.

Furthermore, cable labels, which can be applied as overlapping wrap-around labels or flag labels, use flexible films to avoid an undesired opening in the working environment, combined with highly cohesive pressure-sensitive adhesives.

A critical requirement for identification and warning labels is the print’s resistance against abrasion, scratches, temperature, and chemicals, as well as the weathering resistance for labels used outside.

Pressure-sensitive adhesives

Pressure-sensitive adhesives adhere instantaneously to various surfaces when applying slight pressure and can be based on different coating technologies and chemical compositions. Applications described in this article require adhesives that can withstand severe working conditions over an extended period. Of all the different adhesive technologies and base polymers available, a selection has to be made.

| Chemical Composition | Rubber | Acrylate | Rubber hybridized acrylic | Silicone |

| Coating Technology | Solvent / Emulsion / Hotmelt | Solvent / Emulsion / UV-cured | Solvent | Solvent |

Figure 4: Overview standard adhesive technologies

Rubber-based adhesives

Pressure-sensitive adhesives using rubber polymers offer high initial tack combined with good flow properties. These properties make them ideal for applications such as cardboard and tires. Disadvantages of rubber-based adhesives are their limited temperature resistance and the degradation of the molecules after exposure to sunlight or heat, resulting in an irreversible loss of performance and a limited lifetime expectation.

Acrylic-based adhesives

Acrylic-based pressure-sensitive adhesives are the best choice for industrial applications in which labels and tapes have to perform over a long time. They fulfil the need for high resistance against heat, thermal cycles, humidity, chemicals, and weathering — typically expressed in transportation and e-mobility. The initial tack and tendency to flow generally are lower than rubber-based adhesives; it can take up to 24 hours to reach the final peel adhesion.

Acrylic-based adhesives – coating technologies

Pressure-sensitive adhesives are processed in a liquid form. They can be diluted in solvents, emulsified in water, or coated as a 100% system with photoinitiators added.

Even though the solvents or the water are fully evaporated (and recovered) during the drying process in the production of self-adhesive materials, the final product’s adhesive properties will differ, depending on the liquid carrier. Because acrylic polymers are not soluble in water, they need surfactants to be supplied as an aqueous solution. These surfactants remain in the adhesive layer and are responsible for lower humidity and chemical resistance of emulsion-based acrylic adhesives versus solvent-based alternatives.

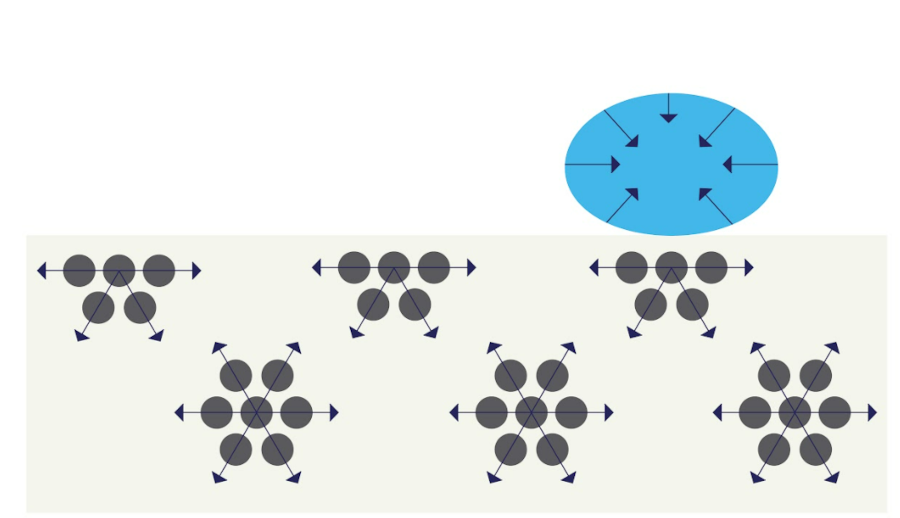

Figure 5: Emulsion acrylic adhesive with surfactants

Acrylic-based adhesives – labeling plastics and other difficult substrates

More and more parts in the technical industries are being manufactured of plastics instead of metals, and surfaces are being engineered to be dust and dirt-repelling. With these design considerations, the surface energy of labeled parts is steadily decreasing.

Figure 6: Surface energy of typical substrates

Pressure-sensitive adhesives are high-viscosity liquids that initially need a good wet-out onto the substrate before their molecules can interact to create adhesion. If the substrate’s surface energy is lower than the surface tension of the adhesive, wetting out cannot occur — a principle we can witness when raindrops fall onto a freshly waxed car.

Figure 7: drop on low surface energy substrate

Figure 8: drop on high surface energy substrate

Pure acrylic adhesives do not offer sufficient peel adhesion on low surface energy substrates like PE and PP. To overcome this, resins are typically added to the formulation to increase the tack and the final peel adhesion. The type and amount of the resin determine the adhesive properties. Resinated adhesives are also referred to as tackified or modified acrylic adhesives.

Rubber hybridized acrylic adhesives

As described above, acrylic adhesives offer the best properties regarding resistance against elevated temperatures, UV light, and chemicals. Due to their relatively high surface tension, resins must be added to enable bonding onto low surface energy substrates. Rubber-based adhesives bond well to low surface energy substrates but do not offer the high durability expected for long-life technical applications.

Rubber hybridized acrylic adhesives combine the advantages of these two technologies. Using an acrylic backbone with rubber chains attached, the adhesives feature the high, desired resistance properties of acrylic adhesives, coupled with superb adhesion properties, especially, but not limited to, plastic parts or lacquered metals. Typically it can take up to 72 hours to build up the final peel adhesion of up to 30 N/25mm.

Silicone-based adhesives

While most pressure-sensitive adhesives use rubbers or acrylates as base polymers, in some cases, silicone is used to design an adhesive for a tape or label application. With their special performance, these materials can stick to siliconized surfaces such as airbag fabrics. In addition, removable adhesives with excellent detachability, also after severe storage conditions (including heat and high humidity) are available.

Post-application curing

Pressure-sensitive adhesives usually do not dry or cure after they are applied onto the substrates, but rather stay in place due to their high viscosity and adhesion. When extremely high shear properties or high ultimate adhesion are required, special adhesives can be further crosslinked by applying temperature or UV rays.

FILMS

Pressure-sensitive adhesives can be used as single-layer, unsupported tapes for mounting purposes. In many cases, though, these adhesives are used together with paper and, more likely in technical applications, with a film.

For most applications, polyester films are ideal. They are available in different calipers and colours and offer high resistance properties and dimensional stability, leading to long-term durability. Polyester films containing a high percentage of recycled resin from post-consumer waste are available.

If ambient temperatures in some areas of vehicles can become higher than 150°C, polyimide films are used.

Even though the usage of PVC films is not deemed sustainable, there are good technical reasons in some instances, including wrap-around or flag cable labels. Here the high flexibility, flame retardancy, and UV stability make PVC technically a very good candidate.

In addition to the standard materials described above, customized or application-specific materials are used to provide the required performance.

ADDITIONAL FUNCTIONAL FEATURES

New pressure-sensitive materials are continuously engineered to meet evolving technical requirements. On top of this, additives are often added to adhesives, films, and coatings, providing additional technical aspects—including specific electrical or electrostatic properties, thermal conductivity or insulation, flame retardancy, or colours.

Pressure-sensitive adhesives, films, and additional features can be combined to create materials that enable the production and identification of electric vehicles and their components. Knowing technical requirements and specifications, material manufacturers support choosing the correct parameters to formulate the perfect pressure-sensitive material for each application.

Technical Marketing Manager – Durable Goods Labelling

Labels and Packaging Materials Europe Avery Dennison

AVERY DENNISON’s SOLUTIONS

Avery Dennison does not only produce label and functional materials, but also develops and manufactures pressure-sensitive adhesives and film coatings. We offer seven different adhesive technologies and films with dedicated coatings and a full portfolio of RFID inlay solutions to help enable the design of high-performing solutions required in electric vehicles. Our product portfolio includes a broad range of bonding solutions, pressure-sensitive adhesive solutions for protection, insulation, and cell wrapping, as well as materials for producing instruction, warning, and identification labels, optionally including RFID tags.

With ambitious sustainability goals in place, Avery Dennison focuses on innovations that enhance the circular economy and reduce the environmental impact of processes and products. Dedicated and experienced teams support making e-mobility even more sustainable.