Michael Kiener and Bruno Nunes-Silva

Modern cars resemble a moving data center. The reason for this is the transformation that the electrical/electronic (E/E) architecture of vehicles is currently undergoing. Instead of the complex network of a growing number of Electronic Control Units (ECUs) and microcontrollers, a powerful server architecture provides all the electronic vehicle functions. Previously, almost every single function or functional area was integrated into the network with a dedicated ECU. This has led to a very heterogeneous and complex architecture of embedded systems, which was no longer suitable for further innovations such as the connection of the car into the Internet of Things (IoT).

For as long as the vehicle had been an “island network on wheels”, the complex network of individual ECUs was not a problem. But for the car to be able to provide its occupants with digital services, communication tools and infotainment, it requires a new E/E architecture. With the existing network structures, it is difficult to connect functions across domains and via a wireless interface to the Internet or the Cloud. Updates over-the-air (OTA) are limited to specific functional areas, while a significant increase in the functional scope of the complete vehicle usually comes with a facelift or even a new vehicle generation. Current E/E architectures cannot fulfill the driver’s or purchaser’s wish to personalize and adapt the car to their use. This illustrates that the “one ECU – one function” approach has had its day.

Software as new Heart of the Vehicle

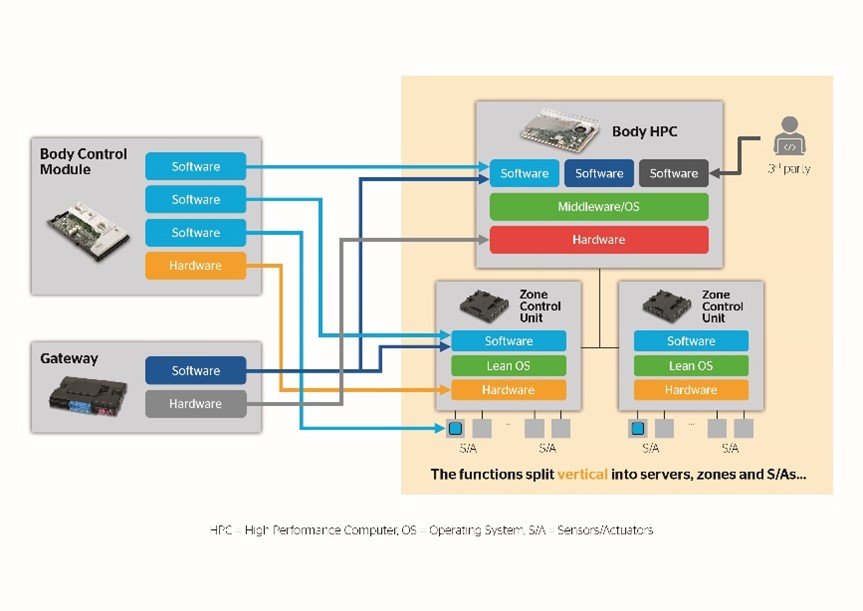

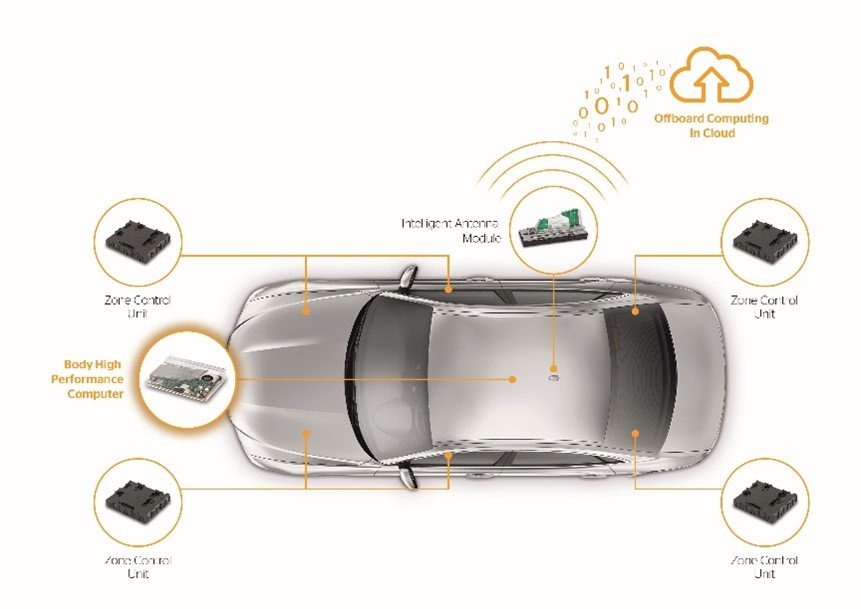

To enable the foreseeable trends, future E/E architectures must be centered around powerful software architectures to drive a strong function and service-oriented set-up, whereas a limited number of high-performance computers (HPCs) or servers provide the capabilities for the necessary functional centralization. These are supported by zone controllers form further essential elements in new E/E architectures to handle the input/output (I/O) logic to the sensors and actuators, as well as for time critical functions (Figure 1). One example for such a server is our Body High Performance Computer, which combines gateway functionalities with the functional scope of a body controller. As central data node in the vehicle and link to the outside world via a connectivity module (e.g., Telematics Unit or an Intelligent Antenna Module), the Body HPC is also an ideal host for connected services (Figure 2). Developing the In-Car Application Server 1 (ICAS1) for the Volkswagen ID series, Continental is the first supplier worldwide to offer a Body HPC as a high-performance server for vehicles with the associated software in series production. In this function, the HPC covers the gateway and body domain controller functions. It coordinates OTA updates and online services and initially provides more processing power and storage volume as necessary, which is only partially utilized at the beginning. Since the HPC provides a memory and processing power of 25 K DMIPS – Dhrystone Million Instructions Per Second – it is possible to install new software or updates at any time. The HPC also coordinates the connection to a backend and the applications available there. With this, architectures continue to evolve, and a stronger cross-domain functional integration will come into place.

Figure 1: HPC as hardware basis of future E/E architectures

Figure 2: Main functions of the Body HPC

On the hardware-side the HPC includes a microprocessor with external memory and multi-core technology. It provides high-speed data interfaces and uses hypervisor technology to support virtualization. The middleware also supports Gigabit Automotive Ethernet, providing the necessary data throughput for the applications. The high-performance computer fulfills central requirements such as consistent hardware-software separation by means of the basic software developed by Elektrobit based on AUTOSAR adaptive, virtualization (multiple operating systems on four virtual ECUs), functional safety (ASIL, non-ASIL), the requirement for new business models and the integration of numerous software sources. Overall, Continental’s HPC concept is divided into four application areas: the Cockpit HPC, which interacts with the driver, the Body HPC that regulates the data streams in the vehicle and serves as an intelligent interface to the internet, cyber security and communication, the automated driving (AD) version of the HPC and the Safety HPC. This fourth application area is currently being developed with the goal to bridge the gap between body domain and AD and to provide functional safety for high ASIL levels. Continental HPCs are developed and built in-house, partly by the corporate subsidiaries Elektrobit (operating systems, virtualization, OTA, and Software Services) and Argus (cyber security).

Zone Control Units – Essential elements for tomorrow’s vehicle architectures

A central driver of the transformation of the E/E architecture from multiple ECUs to an HPC server infrastructure is the introduction of a new intermediate layer with zone control units (ZCUs, Figure 3). ZCUs can be used to “clean up” existing E/E architectures, so to reduce the number of ECUs and the weight of wiring harness. It must be managed by an HPC. The more the central computing power of the vehicle is being concentrated in a few HPCs, the more important become zone controllers that ensure the reliable execution of the vehicle functions. ZCUs serve as intermediaries between high-performance computers and sensors or actuators. Thereby, each ZCU integrates functions from different domains in a specific zone and serves as hub for the power distribution and data connection requirements for the connected devices.

Instead of connecting every sensor, peripheral and actuator directly to a domain controller, they are linked to a local zone controller. The ZCU takes over functions for the respective area of the vehicle for which it is responsible. In this way, the ZCU relieves the HPC of functional surgical effort so that it can concentrate on its actual task, acting as “electronic brain” for data and functions management in the vehicle and beyond. In addition, the ZCU performs local data transformation, aggregates the data, and forwards it to the HPC via Ethernet network. This set-up allows the ZCU to take over the control of the connected devices cross-domain, whereas the HPC can concentrate on the processing of the information. The introduction of ZCUs “frees” the software from the hardware and creates the prerequisite for continuous updates and improvements to the “lifelong learning” vehicle. Continental offers a scalable platform to meet all market requirements.

Agile Software Development

Nevertheless, the increasing number of software applications and services poses major challenges for all actors – partners and suppliers – involved. Therefore, Continental has launched an automated Software Factory and relies on agile development methods. Development is a small-scale task and the expanding software scopes must be coordinated and managed efficiently. For this purpose, Continental relies on an automated gating and transparent metrics to continuously evaluate the software quality down to the source-code level in real-time. All quality-relevant information is available to the scrum teams as well as to internal and external stakeholders. With this agile and automated work, the software attains a high degree of maturity at an early development stage.

Figure 3: Structure of implementation layer of ZCUs

Figure 4: Automated software integration process via the Continental Cooperation Portal

The selection and adaptation of development methods and project scaling is based on an agile framework. As a development platform for ongoing, seamless software review serves GitHub, which could be integrated into the Continental DevOps portfolio. With GitHub, an automated pipeline was created, which integrates tools such as Jira and Grafana to verify all changes. To ensure the safe integration of third-party suppliers, the DevOps ecosystem also includes standard tools such as Prometheus for monitoring, Elasticsearch for data recording, Jira for tracking problems, Confluence for documentation, Artifactory for binary storage, Kubernetes for the build infrastructure and others. Two to three software releases are provided every day. The testing is also exclusively automated. With a conventional development process and manual steps, the scope and pace of the development of the HPC software would not be possible.

Automated Testing and Approval

In order to optimize the underlying processes of the software development, Continental has also established the Continental Cooperation Portal. Instead of the previous “ping-pong match” between software delivery, testing and validation, it automates these processes and restores data in the event of errors. This guarantees that only error-free applications are transferred to the actual development system (Figure 4). The portal itself is a secure, standardized interface for all stakeholders, internal as well as external. Users have access to software libraries and open documents, and they can develop software. This software goes through an automatic testing and pre-integration process. After approval it is added to the main line. Errors in the code are reported very quickly and can be fixed in short iterations. By automating these process steps, the Continental Cooperation Portal enables faster software development and software at higher quality with a growing number of external and internal stakeholders.

Summary and Outlook

Software and data will dominate the cars of the future and lead on the long term to a profound transformation of the automotive ecosystem and industry. The greater the role of software, the more important standardized hardware and operating systems become – one of the reasons why HPCs will be the standard of future vehicle E/E architectures. But the HPC server concept would not be future proof if it just covered the current demand for connected cars. Both its processing power and storage are designed to enable new data- and service-based business models. So, overall, the HPC is the cornerstone of future vehicles – moving away from distributed to server-based E/E architectures. This allows overall E/E-architecture optimization as well as features upgradability and updateability over the vehicle’s lifetime. Another future trend is the integration of few but powerful cross-domain HPCs in one vehicle as a possibility to move functions from one server to another, which increases the flexibility of the concept as well as the redundancy and reliability of the electronic functions.

- Michael Kiener

- Michael is the development manager of the Body and Network Control department at Continental, which develops high-performance computers, among other things. With many years of experience in the field of software development, quality management and management functions. Michael is an engineer and holds a degree in electrical engineering from the Friedrich-Alexander University in Erlangen-Nuremberg, Germany.

- Bruno Nunes-Silva

- Bruno is a portfolio manager for the Body and Network Control department at Continental. With many years of experience in the fields of product and portfolio management, as well as strategic marketing, Bruno graduated with a degree in International Business Administration from Furtwangen University, Germany.