by Eric Verhulst, CEO/CT – Altreonic-Kurt.energy

Battery power is gaining a lot of attention in the search for a cleaner world. Electric energy is clean and silent. The disadvantage is that electric energy is like water flowing from a mountain stream. It must be used when it is generated, or else, it is wasted. This is why we need batteries that store electric energy. Most batteries use a chemical reaction generating a flow of electrons and ions between electrodes, which in turn provides an electrical current. This current of electric energy can be used—in theory—to do everything from powering a car to stabilizing a power grid.

The problem with most batteries, however, is that they can’t store and release the electrons very efficiently yet. Thus, we have to use large and heavy batteries, often racks of them, to do the work of a single combustion engine.

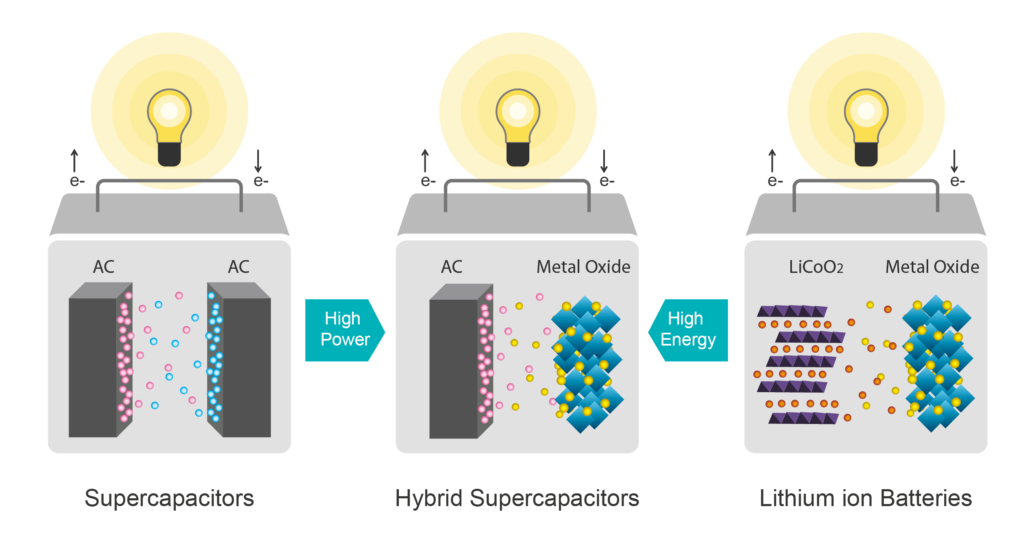

The reason why comes down to the electrons. Electrons are very tiny. In classical electrochemical batteries, we actually store them using a reversible chemical reaction. Typical examples are the classical lead-acid car batteries and the now widely used lithium-ion ones. Capacitors, on the other hand, store the electrons statically. This allows for very fast storage and release. However, because the electric charge is mainly a surface phenomenon, capacitors can’t hold much energy. Ironically, the tiny electrons are the reason that batteries and capacitors are heavy as the resulting energy density is much lower than of the fuels used in combustion engines.

And, there are further problems with the current designs. Lithium-ion batteries, for example, can short circuit over time. When that happens, it can start a fire in the whole battery pack. Here, the culprit is not the electron flow, but the redox reaction and the flammable electrolyte. As well as this, batteries suffer reduced energy efficiency in freezing as well as hot temperatures, and have a limited operating life, suffering reduced performance over time.

Thus, we need a better battery to overcome these challenges.

So, in search of a better battery, what is a better battery?

An outstanding battery must be practical, sustainable, and safe. The main requirements are a high(er) energy density, combined with more power output, in addition to a lighter overall weight and safer design. This means we need a battery the capability to store and release more electrons faster, and to do so in a smaller, lighter battery. In addition, we need one that works for a lifetime, and at high and low temperatures without compromising energy storage or output. The lifetime requirement is one of the most important ones when it comes to sustainability and being practical to use.

A better battery is light as a feather, fits easily in your car, and powers it reliably and safely forever.

Best practice: the complexity of Li-ion batteries

The most widely used batteries today are variants of Lithium-ion. In cars, the Lithium Nickel Manganese Cobalt oxide (NMC)-type dominates, because they have the highest energy density. Energy provides range. But cars, and many other applications, also need power, i.e. the capability to charge and discharge quickly. Here, we hit a roadblock.

The most widely used batteries today are variants of Lithium-ion. In cars, the Lithium Nickel Manganese Cobalt oxide (NMC)-type dominates, because they have the highest energy density. Energy provides range. But cars, and many other applications, also need power, i.e. the capability to charge and discharge quickly. Here, we hit a roadblock.

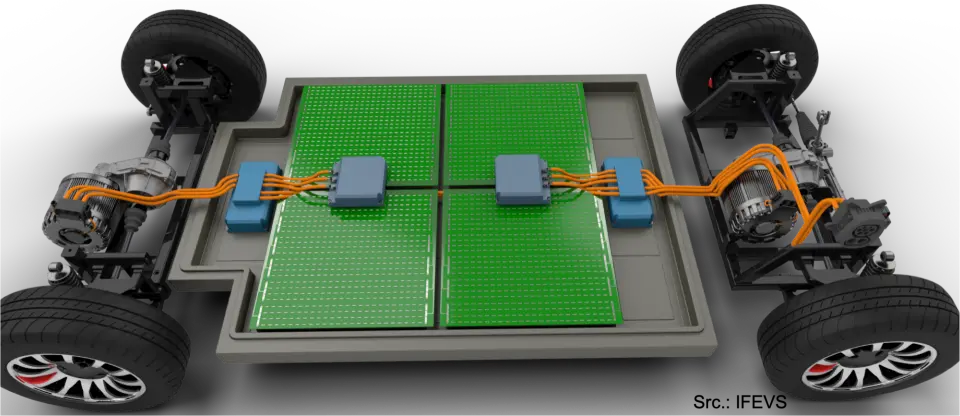

Power requires current, and in conjunction with the unavoidable internal resistance, this generates heat. The heat is quadratic with the current and this is the main cause of cell degradation, not to mention fires. Hence, such batteries are not just a collection of cells, but an elaborate mechanical construction with liquid cooling, sensors, and software-driven controllers that carefully manage and monitor the battery (see the picture on the left exposing part of a Li-ion battery pack). This can increase the weight and volume by a third. If such a battery fails, then it is a costly operation to replace it. And in the event of a fire, the entire car may have to be replaced.

The alternatives: a trade-off war

There are, of course, alternatives to NMC batteries. Lithium FerroPhosphate (LFP) batteries are safer, but have less energy and power. Lithium-Titanate (LTO) batteries have a better lifetime performance and more power, but even less energy. There are alternatives to lithium-ion as well.

Solid-state batteries do away with the flammable electrolytes and can store more energy, but this results in very low power densities. Other batteries use different materials, such as lithium-sulfur, and recently, silicium. These are promising improvements, but to meet all requirements for a better battery in a volume production process is not a trivial step.

None of these designs alone give us the featherlite, safe, and efficient battery we need. So what can we do?

Going hybrid

As no battery technology on its own can provide the best in class for all parameters, why not combine them? Lithium-based supercapacitors are good at most of the parameters, indeed, often even too good on power capability, but are poor at energy density.

As no battery technology on its own can provide the best in class for all parameters, why not combine them? Lithium-based supercapacitors are good at most of the parameters, indeed, often even too good on power capability, but are poor at energy density.

Hence, we have developed a hybrid device using activated carbon (a variant of graphene) as one of the electrodes. We then use a classical lithium compound as the second electrode. The result is a cell architecture that works like a capacitor in terms of power and storage, but also delivers a decent energy density.

As the main active component is carbon, it needs less lithium, which reduces costs and is better for the environment. Depending on the lithium compound used, we have cells optimised for power or for energy. While the hybrid power capacitors deliver 80 to 100 Wh/kg, they can be charged very fast and deliver up to 20 times their nominal power. The hybrid energy capacitors deliver 230 Wh/kg and can deliver up to 1,5 times their power with no active cooling.

In addition, this battery needs no cumbersome and heavy Battery Management System, most often no expensive cooling or heating (as the temperature range can be from -40 to 80°C). It provides decent power capability, is inherently safe, and easily lasts between 10 to 30 years (or 1 million miles).

The benefits of going hybrid

While the energy density of our battery is not spectacularly better than the best Li-ion cells, this is compensated for by the other parameters. It can deliver the power when needed in a smaller package

While the energy density of our battery is not spectacularly better than the best Li-ion cells, this is compensated for by the other parameters. It can deliver the power when needed in a smaller package

As well as this, it can be charged relatively quickly. It can reach up to 75% of its nominal capacity in 5 minutes although the latter requires a corresponding charging infrastructure that is not yet common. Moreover, it doesn’t suffer from cold or heat and will no start to burn when abused. As one can see in the picture, the resulting battery pack is very dense, yet very straightforward to put together. It’s very robust and simple and therefore resulting in a very trustworthy battery that will last a lifetime without any fire risk.

The challenge: driving an e-car like a classical one

So, a battery needs to meet several often conflicting criteria to be an ideal solution, from the technical point of view. What is more, in the case of electric vehicles, the results must also be acceptable to the market. Is it practical to use? Is it better than (or at least as good as) what people are using now?

Today’s fuel based cars are convenient to use. You can fill one up in a few minutes, and you can easily pass a 1000 km before the next fill-up (depending on the journey). Given that the energy density of fuel is 80 to 100 times higher than the energy density of batteries, achieving the same result is a tough challenge.

The solution is to work on multiple fronts, and there are still hurdles. Firstly, charging in 5 minutes requires charging at 12 times the nominal power. Only hybrid power capacitors can provide this with an acceptable energy density. One should not underestimate the impact on the charging system; currents will be very high. Secondly, we must consider vehicle efficiency. While a Hyundai Kona Electric recently set a range record of 1026 km, the driving conditions were very specific, with an average speed of about 30 km/hr. This reduced the energy consumption to 6.2 kWh/100 km, which is two times better than when driven normally. But it gives us an indication of a workable model.

An energy efficient electric vehicle doesn’t need to be a 3 ton SUV that accelerates like a sportscar. If the vehicle is designed from the start as a “battery on wheels” and the energy consumption can be reduced to 5 kWh/100 km, which is a mostly a matter of weight and drive train efficiency, then a 32 kWh power capacitor battery will provide for about 600 km range that can charge 475 km in just 5 minutes with a 360 kWh charger. That charger in itself can be a 30 to 40 kWh powercapacitor battery reducing the need for a high power grid connection. Our e-vehicle might not be a sportscar but at least it is a practical and an economical car to drive.