Flexible And Efficent Electromagnetic Shielding

Dr. Erek Speckert

The increasing number of registrations for hybrid electric and fully electric cars leads to the need for high EMC compliance. Additional requirements result from the importance of autonomous driving. A flat wire mesh offers promising shielding properties being associated with many adjustable product characteristics and features.

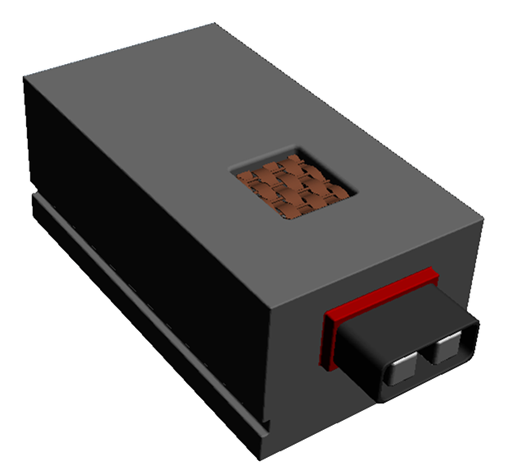

Figure 1: Different delivery forms of the flat wire weave.

Introduction

A small mesh size allows a high surface coverage of a flat wire weave due to the involvement of the flat wire itself. This results in a high suitability for electromagnetic shielding. Consequently, very good shielding effect from the short-wave to the microwave range can be demonstrated. Additional advantages of this kind of weave are high spatial flexibility and vapor permeability.

The use of the fabric in an integrated shielding concept combined with other shielding materials is a promising option to meet system requirements. Joining technology to sheet metal, stamped or stamped bent parts are of great importance. Insert molding for the realization of plastic composite parts is also essential.

CARS: ELECTROMAGNETIC RADIATION AND SHIELDING

The electrification of the drivetrain on the one hand and the sensors for autonomous driving on the other will gain increasing importance of electromagnetic compatibility in the future. For example, in power electronic modules between the electric motor and the battery, high electrical currents are converted in short times. Switching frequencies of power electronics in the range of a few kHz, leads to strong electromagnetic emissions up to the GHz range. In case of an insufficient shielding, these can interfere with sensitive sensors or sensor signals. This in turn could be of drastic consequences during autonomous or connected driving.

In addition, it is also possible that other automotive sub-systems like infotainment systems or control units are disturbed. This is of utmost relevance for the function or customer. But also the sensitive control and monitoring units of traction batteries in hybrid electric vehicle or battery electric vehicles have to work without interference in order to ensure the energy supply of the motor. This requires a proper EMC shielding and filter design

INTEGRATED EMC CONCEPT AND PRACTICAL RELEVANCE

A proper EMC concept includes consideration of all structural levels of the car, which means semiconductor devices, components and system level. Only considering all levels and their interactions ensures the electrical functions of the overall system. Therefore, EMC has to be taken into account in early stages of development and design. The described flat wire weave shows high effectiveness at the component/system level, where the use of filters and shielding is a key issue. At higher levels the interaction of signals like interference as well as EMC simulations are more important.

Examples for cases with high significance for shielding are:

- Inductive charging with typical frequencies in the range of 75 to 90 kHz, an alternating current is induced in the receiver coil. Shielding is necessary to limit electromagnetic fields during the charging process and to avoid secondary radiation that occurs during rectification.

- Switching frequencies of semiconductor components for controlling the electrical machine, especially signals generated in acceleration and braking processes cause radiation with typical frequencies in the range of 2 to 3 kHz.

- Shielding the entire high-voltage harness in voltage range between 48 and 800 V allows its reliable function.

- Interference signals in the low-frequency range are also important. For example, those signals are generated in acceleration and braking processes.

- The increasing legal framework shows the high importance of EMC. In this context, it is obligatory that the ICNIRP (International Commission on Non-Ionizing Radiation Protection) as well as the CISPR (Comité international spécial des perturbations radioélectriques – international special committee for radio interference) have to be taken into account. The focus is on both the protection of the driver and the technological robustness with regard to electromagnetic interference.

BENEFITS OF FLAT-WIRE-BASED EMC WEAVES

- Very robust despite its low weight

Material determines the physical properties and formability. These can be tailored to the requirements. - Exactly definable weave properties:

Mesh size and cross section of the wires based on customer needs. - Suitable for complex installation situations:

Weave shows high flexibility and can be easily brought into any geometric shape (e. g. punching and embossing).

The wire meshes can be made from flat wires of copper, aluminium and its alloys. The weaves can be made with flat wire in one or two spatial directions. If the flat wire is used in only one direction, the warp wire is designed as a round wire. The flat wire is used in the weft direction orthogonal to this. Alternatively, it is also possible to design the warp wires as flat wire (see Figure 2).

Figure 2: Different realizations of flat wire weave.

CENTRAL SHIELDING MEACHANISMS OF THE FLAT WIRE WEAVE

The damping of an electromagnetic field by a weave is higher, if the weave shows a large number of small holes compared to a weave with a small number of big holes. Therefore the mesh size is an important parameter. Moreover high conductive materials allow the circulation of eddy currents. But also good contacts at the crossing points are important for the generation of eddy currents and the damping opposing fields. Thus, the occurrence of slots must be avoided.

In the following, an exemplary measurement of a flat wire weave is described. In this case, the flat wires consist of pure copper (Cu-ETP1) in the weft direction with a cross-section of (1.250× 0.100) mm². The warp wires made of CuSn6 are round wires and have a diameter of 0.06 mm. The mesh size is about 100 μm in the x-direction and about 250 μm in the y-direction,

Figure 3: Measurement of the shielding effectivity of the flat wire weave.

The shielding effectivity is determined using the practical principle of insertion loss [EN 50147-1 96]. The test specimen is inserted between the transmitter and receiver coil. A measurement without a specimen is performed as a reference. Accordingly, the shielding effectiveness can be calculated.

For frequencies in the kHz range, the shielding effectiveness is measured using magnetic antennas, as shown in Figure 3 (left). The result for electromagnetic fields in the high MHz as well as GHz range can also be seen in Figure 3 (right).

Considering the frequency range from 10 kHz to 4 MHz, an approximately linear magnetic shielding effectiveness up to 45 dB is obtained. The electrical shielding effectiveness in this range should not be considered critical for this material due to the Faraday effect. Electromagnetic shielding effectiveness in the 30 MHz to 3 GHz range is 20 to 80 dB.

Weaves for electromagnetic shielding are already commercially available in a large number of variants made of round wire. These are inferior to the weave described here in terms of shielding effectivity. For example, the attenuation values there are generally around 60 db in the low MHz range.

APPLICATION OPPORTUNITIES

To sum up, in installation situations with high manifold requirements and high demands, the flat wire weave is of advantage, due to its spatial flexibility, permeability for gases and vapor as well as optical transparency, as exemplarily shown in Figure 4.

After the development of the weave itself, we focus on joining technologies which allow reliable connection to other metallic parts. Therefore, combinations of shaped weaves with metal sheets, stamped or stamped bent parts or (contact) springs are conceivable.

Given our broad technical expertise, Kern-Liebers is positioning itself as the forerunner of innovative solutions for new powertrain concepts and proactively develops with its customers the technologies of the future. Applications within electric vehicles are, of course key focus of our efforts”,

says Dr. Erek Speckert, CEO & President of the Kern-Liebers Group.

The combination with plastic (composite) parts is also an interesting possibility for covers and housings with a high shielding effectivity in the context of lightweight design. As shown in, vapor and gas permeability could also be realized by using windows. Consequently, similar sensor housings have high potential as safety elements, for example for applications in battery technology, see Figure 5.

In this way the customer is able to come back on other core competencies of Kern-Liebers and gets tailored solutions from a single source.