EV technology is arguably at a very early stage of development. Future growth requires a completely new mindset from all players to push innovation, and make e-Mobility attractive and possible for high volume markets. Miniaturization of all components, including connectors, will be important, as will reducing the number of cables in the car, whilst simplifying the serviceability of systems will also be key.

The demand for electric vehicles is booming around the world, not only due to stricter international environmental regulations, but also consumer demand. The better performance, greater range and reduction in costs, makes driving an electric vechicle more appealing.

Current Status of EV Charging

Currently there are multiple charging standards in the world. CHAdeMO was the first to be introduced, followed by CCS (Combined Charging System) throughout Europe, North America, GB/T in China and OEM-specific charging interfaces.

Charging systems play a key role in supporting the power grid. More recently, to promote the introduction of renewable energy sources with large output fluctuations, the practical application of advanced systems such as V2G (Vehicle to Grid) and V2H (Vehicle to Home), which control the charging and discharging of EVs, have begun.

Wide Variety Interface Connectors for EV Charging

Wholly owned by Japan Aviation Electronics Industries, Ltd., Tokyo, Japan (JAE), JAE Europe Limited has been developing a series of interface connectors for EV charging since 2010, the dawn of EV popularization. Our first development, was a quick-charge connector that meets the CHAdeMO standards and has a long track record since it was launch in 2011. In response to the worldwide diffusion of following CHAdeMO standards, UL and CE-certified products are a requirement to satisfy the global demand, and are now widely used throughout Europe, North America and Asian nations.

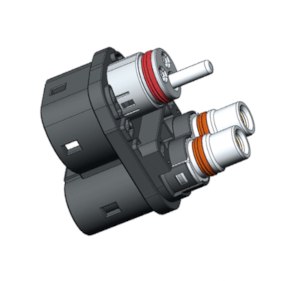

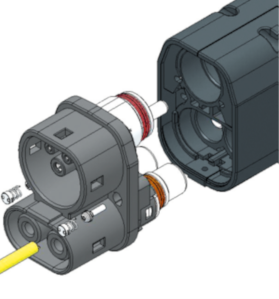

The CCS Type-2 standard’s quick-charge connector interface is fast becoming the de facto choice for the European market. There is an increased call across the charging interfaces to make solutions as low maintenance as possible.

In order to reduce the total costs, one possibility is a product that has structure that allows only the mating part of the connector to be replaced. To ensure safety, a double insulation structure that protects the live components of the connectors from water is recommended. That kind of structure prevents short circuits caused by water ingress even if the exterior is damaged due to unexpected circumstances. This safety-design structure was adopted from the CHAdeMO specification, which has proved to be highly reliable.

The Ever Increasing Demand for V2X CE-Certified Solutions

With the market demanding more and more sollutions for V2X (IEC 62196 -1 -3) ranging from 25A to 60A the need for UL and CE certified product has increased. The benefits of mid-range cable solutions are their lightweight and compact design.

The V2H Guideline set by CHAdeMO specifies a charge/discharge connector system. This system utilizes the large-capacity batteries installed in EVs as a V2H discharge product for homes and offices, and V2G to regulate power supply and demand over a wide network.

CHAdeMO has lead the standardization in charge/discharge systems, such as V2H, and are now in practical use in Japan. As demonstration projects are proceeding in Japan and Europe and other countries, JAE has been the first company in the industry to acquire the CE marking for the KW02 series*.

(*According to market survey as of October 2019)

Authors: Stuart Denny (Senior Sales Manager) and Levon Altunyan (Product and Marketing Manager) at JAE Europe Limited