Electric Vehicle Battery Housing Market: An Arena of Innumerable Opportunities

Aashi Mishra

Consumer interest has been rising in purchasing electric vehicles in recent years. It has been estimated that annual electric vehicle sales are projected to reach almost 30.1 million by the year 2030. The market for electric vehicles is evolving towards diversification and there are numerous varieties available in various price segments. Various market players are dedicated to manufacturing various components of electric cars such as battery packs/cases, electric motors, charging systems, etc. In this blog, we will have an in-depth exploration of the electric vehicle battery housing market.

The battery in the electric vehicle is no less than the heart of the car. Also, the battery is the most expensive and heaviest component in the car. The lifespan of the battery depends on the design of the cells and the type of housing used. The housing can be made up not only of metal but also of modern innovative ultralight plastics. Let us understand how electric vehicle battery housing affects an electric car. The functions of car battery cases are as follows:

- Protects the battery from thermal, mechanical, and chemical damage

- Provides ventilation to optimize heat distribution

- Provides “structure” for the modules and ensures that the battery remains in place

All of these factors mean that battery car housing must be manufactured from efficient materials. Market players are looking for the latest material solutions to generate lighter batteries.

The materials utilized to manufacture car battery housing must meet high requirements in terms of thermal insulation, resistance, and impact strength. The most commonly utilized materials include aluminum, steel, hard plastics, and numerous kinds of composites. Modern foams such as foamed polypropylene and EPP. These materials are efficient for transporting packaging and have also proven to be an efficacious solution for making lightweight insulation systems. The researchers suggest that electric vehicle batteries will have to be almost 50.5% lighter in the future. In fact, the requirement for the lighter vehicles is also surging as electric light commercial vehicle sales globally has increased by almost 70.1% in the 2021. The usage of technologies such as nanotechnology in battery casing are enhancing battery performance and efficacy.

For instance, the electric vehicle battery housing is built for CFRP, and can save up to almost 40.5% weight when compared to steel or aluminum. Let us look into various aspects related to the electric vehicle battery housing market.

Electric Vehicle (EV) Battery Housing Market:

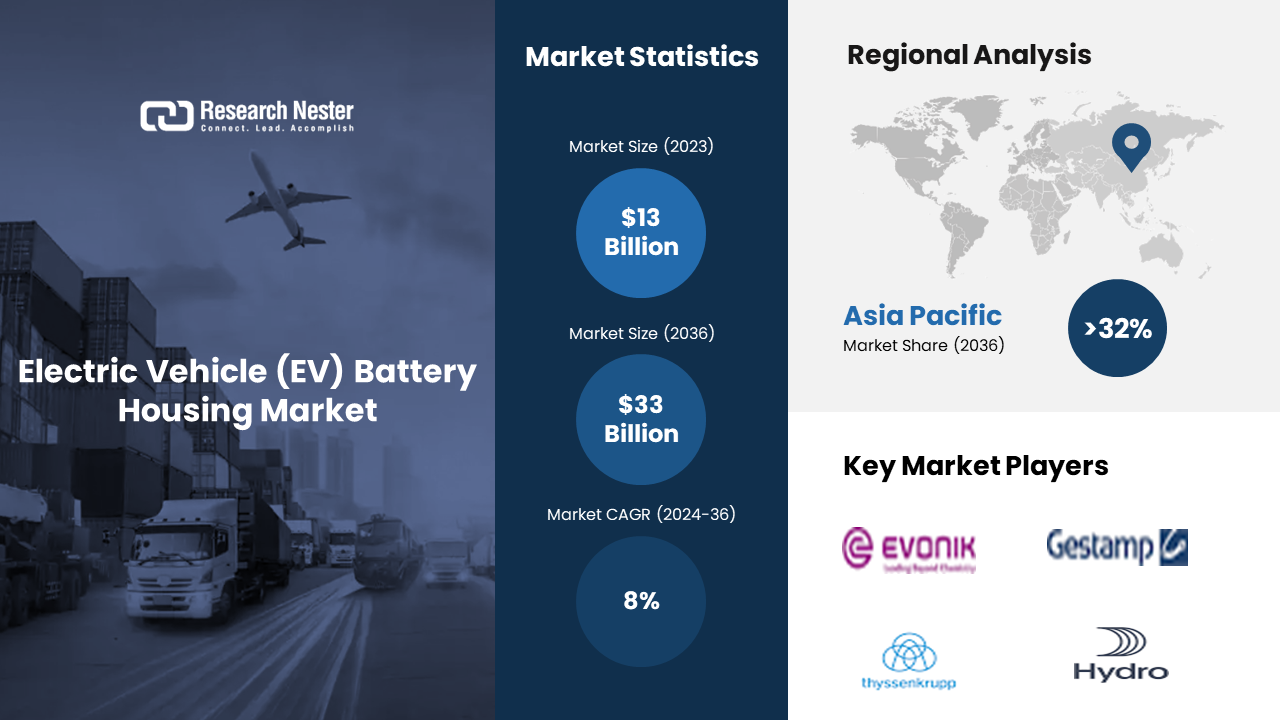

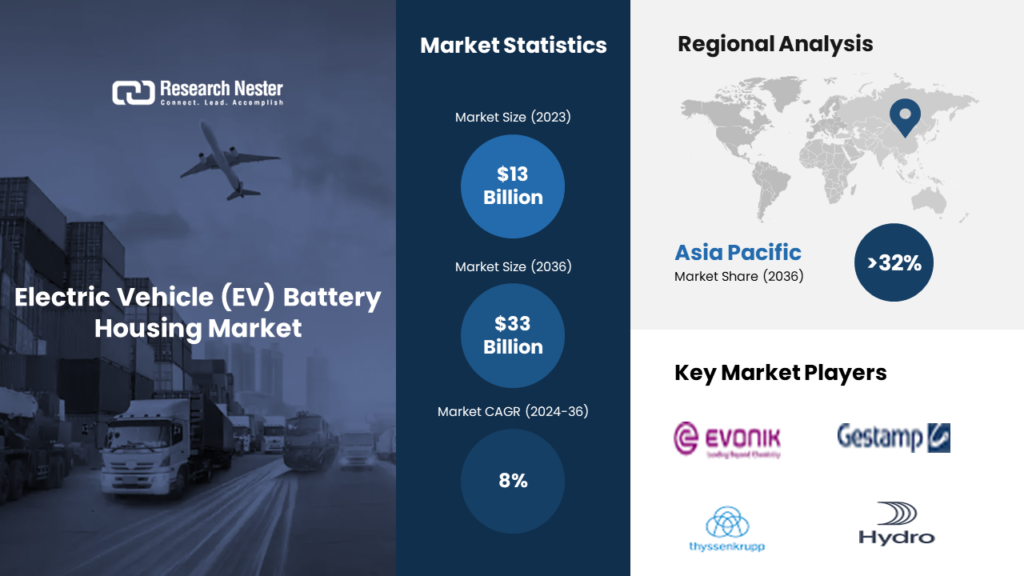

The electric vehicle battery housing market size is projected to cross USD 3 billion by the end of year 2036, thriving at a CAGR of almost 8.1% during the forecasted period. In the year 2023, the industry size of the electric vehicle battery housing market garnered USD 13 billion. The growth driving factors for the market are as follows:

- Increasing adoption of lightweight materials

- Surge in the usage of modular design

- Rising electric vehicle adoption and battery technology advancements

- Increase in laws made by the government for severe pollution

- Rising concerns regarding battery safety

- Rising standards for strong design

However, exorbitant material costs and supply chain vulnerabilities are acting as a hindrance to the growth of the market.

Some of the prominent companies Evonik Industries AG, Gestamp Automocion, ThyssenKrupp AG, Covestro AG, Nemak S.A.B de C.V, Norsk Hydro ASA, Magna International Inc, Kautex Textron GmbH & Co. KG, Novelis Inc, Minth Group.

The market in the Asia Pacific region stood at almost USD 6 billion in the year 2023. The region is expected to continue its dominance throughout the forecasted period. The growth of the market can be attributed to the presence of a robust automotive sector in these countries. Other than this, the second region for the maximum growth is Europe. Here, the growth driving factor in the region is due to the presence of highly active research and development associated with advanced battery technology.

In July 2023, a prominent company Magna declared that the company would invest almost USD 791 million to build the first 2 supplier facilities. Magna will start supplying battery enclosures for the automaker’s second generation.

Moreover, at the beginning of 2024, E-work Mobility signed a partnership with SGL Carbon to supply battery cases made of glass fiber-reinforced plastic. The electric car manufacturer is replacing its currently used aluminum battery boxes with boxes made of glass fiber.

In a nutshell,

The above information illustrates that the market holds innumerable growth opportunities in the future. However, budding as well as established market players are required to understand the intricacies of the market to make sound decisions for business. A comprehensive research report consists of various imperative information such as regional analysis, market constraints, growth driving factors, latest market trends, etc. These factors are necessary for market players to carve themselves a niche in the market and stay ahead of the competition.

Aashi Mishra An experienced research writer, strategist, and marketer with a demonstrated history of research in a myriad