Diving into the Essence of LiDAR Technology

The automotive industry is at the forefront of technical evolution with Advanced Driver-Assistance Systems (ADAS) emerging as a main technology. Beyond reshaping how we use vehicles; autonomous driving will also allow us to optimize energy consumption on our routes.

Already, the first cars featuring ADAS Level 4, defined as ‘high automation’, where the vehicle is capable of autonomous travel under normal environmental conditions without requiring driver oversight1, are available on the market. Ensuring the safety and efficiency of such systems requires sophisticated sensors and imaging processors that provide true-to-life images of the surroundings. Full accuracy and fast reaction times are essential in this field, even at high speeds and in unforeseen situations.

In recent years, one of the most promising advancements in this landscape has been the development and integration of LiDAR (Light Detection and Ranging) systems, an optical method aimed at measuring distances and speed. Unlike other radar systems, LiDAR sensors identify the environment relying solely on light, which is detected by photosensors.

Hamamatsu Photonics, a globally recognized leader in manufacturing optoelectronic components, modules and systems, has been instrumental in developing solutions for LiDAR in the automotive industry. With over seventy years of experience in optoelectronics, three decades of supplying AECQ-qualified components, and three Nobel Prize contributions, the company seamlessly combines extensive experience with an unwavering commitment to continuous research and development.

In this article, we delve into the essence of LiDAR technology, its core principles, emerging trends, and the crucial role of photosensors, unraveling the intricate details that make LiDAR a pivotal technology in the automotive and broader technological landscape.

Main LiDAR approaches

Two primary technological approaches dominate the field of LiDAR: Time of Flight, also called TOF, and Frequency-Modulated Continuous Wave (FMCW), which is based on frequency modulation.

While TOF LiDAR is considered standard, FMCW systems are increasingly gaining in popularity, for reasons such as their potential to overcome some of the challenges associated with the time-of-flight approach. This is particularly evident in the near-infrared range, where FMCW exhibits certain advantages such as enhanced eye safety or increased ambient light immunity. While these challenges can be addressed by using a different wavelength (e.g. 1550nm instead of 905nm), the availability of high-power lasers at an affordable cost for this range remains a hurdle.

However, it is important to note that TOF LiDAR technology is already available and tested, while the TRL (technology readiness level) and automotive reliability of FMCW are yet to be conclusively proven, despite the promising advances.

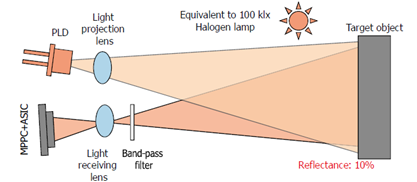

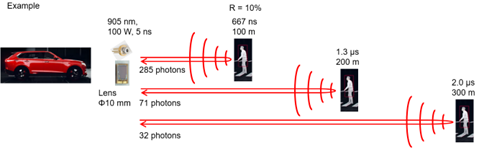

Figure 1: Basic principle of TOF LiDAR

The basic principle of TOF LiDAR is simple: a light source emits a concentrated beam of light that is reflected by an obstacle, such as a pedestrian or a car and bounces back to a photosensor. The sensor calculates the object’s distance, based on the time the reflected light takes to reach it.

The heart of LiDAR technology: Photosensors

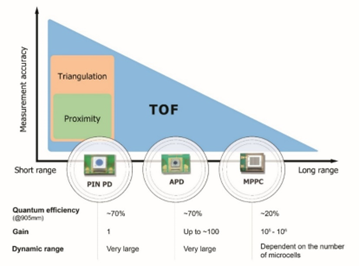

A photosensor is a device that converts light into an electrical signal. There are various types, and each will have its specificities to fit the required need based on measurement accuracy and distance.

Figure 2: Types of detectors for TOF requirements

First, the Silicon PIN Photodiode (PIN PD) is the most common and simple photosensor with high quantum efficiency and without any amplification, making it ideal for short-range detection due to its lack of gain.

When extending the detection range, it becomes essential to have a sensor with higher gain such as the Si Avalanche photodiodes (APD). It allows for detection in low light conditions and increases the speed of detection.

However, for applications requiring the detection of very low light levels, a device capable of detecting single photons with a high gain becomes crucial. The Multi-Pixel Photon Counters® (MPPC®), also known as Silicon Photon Multipliers (SiPMs) or SPADs (Single Photon Avalanche Diodes), feature a unique structure that effectively reduces noise and enables the detection of each single photon.

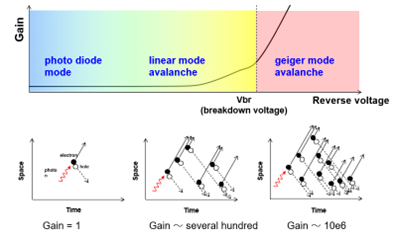

Let’s delve further into understanding what a Single-Photon Avalanche Diode (SPAD) entails. When we apply a reverse bias voltage higher than the APD’s breakdown voltage, technically known as operating the APD in a breakdown state, we are in Geiger-mode operation. As illustrated in Figure 3, in this state, we reach a very high gain.

Figure 3: SPAD’s Geiger-mode operation

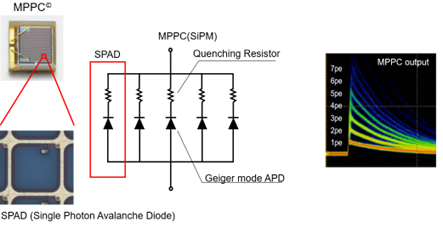

To allow the detection of a second incident photon, it is necessary to add a quenching resistor to suppress the current. This prevents surges from the depletion region once sufficient gain and adequate output signal amplitude have been attained. When multiple SPAD channels are collected into a single output, the result is an MPPC®.

In instances where many pixels fire simultaneously, the output becomes the cumulative sum of the standard pulses. In scenarios where several photons are incident on the same pixel simultaneously, the signal manifests a 1 p.e. pulse as depicted in Figure 4.

Figure 4: Unique MPPC® structure and output

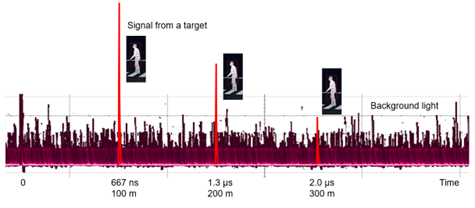

As shown in Figures 5 and 6, only photons with a specific energy can generate an electron-hole pair with enough energy level for detection. Applying these concepts to LiDAR systems reveals that MPPCs are the best detectors for LiDAR applications.

Figure 5: Example of number of photons vs distance using LiDAR system

Figure 6: MPPC® output pulses

While sensor technologies play a crucial role, their capabilities extend beyond light detection to signal processing at the hardware level, offering pre-processed data. Implementing these functions is vital because they allow a reduction in circuit dimensions, increase the robustness of the system, and lower the power consumption – critical factors for the future of electric vehicles.

As most automotive manufacturers have distinct LiDAR designs, each with their own peculiarities and specialties, a universal “one-size-fits-all” design proves less effective. One of the unique services Hamamatsu focuses on is customization – not only for the sensor but also for the Application-Specific Integrated Circuit (ASIC), which can even be integrated with the sensor through a direct bonding technique. This tailored approach empowers us to help our customers find the best solution for their given application and key requirements.

Custom solutions for evolving needs

In addition to our standard products, one of our main value propositions is the possibility of providing custom solutions. Depending on the LiDAR scanning system such as the traditional system or Flash (Flooded Light Array Type) and the exact use case application such as long-range for highway pilots or short-range cocoon systems for parking, a different sensor geometry and function will be needed.

However, customizations extend beyond the sensor level. For example, recently there has been a growing demand for 2D MPPC®s or SPAD detectors that function as image sensors, but with significantly higher sensitivity. This customization could be as simple as changing the gap size between the detector elements in an array, or as complex as designing a whole new ASIC. It could also include complete optical assemblies that combine a light source such as a pulsed laser diode with sensors and bandpass filters.

Hamamatsu Photonics, a leader in photonics solutions, possesses the capability and experience to produce such custom chips, from semiconductor manufacturing to specialized packaging meeting rigorous automotive standards. We cater to a spectrum of customization requests, from simple adjustments to intricate designs, ensuring the perfect fit for our customer’s sensor needs.

The Future of LiDAR: Navigating Challenges and Opportunities

As LiDAR technology continues to evolve, it faces both challenges and opportunities that will shape its trajectory in the automotive landscape. While LiDAR has proven instrumental in enhancing the capabilities of ADAS and autonomous driving systems, the industry grapples with issues such as cost, limited field of view, and the need for standardization2. As vehicles equipped with LiDAR become more commonplace, addressing these challenges becomes paramount to realizing the full potential of this technology.

Looking ahead, the future of LiDAR holds the promise of safer, more efficient transportation and a host of applications that go beyond the automotive realm. From enabling precise drone deliveries to enhancing the capabilities of robotics in industrial settings, the impact of LiDAR extends far beyond its initial applications.

In conclusion, diving into the essence of LiDAR technology reveals a landscape that is both dynamic and full of potential. Hamamatsu Photonics, as a key player in this field, continues to shape the trajectory of LiDAR through innovative solutions, customizations, and a commitment to addressing the challenges that lie ahead. Beyond technological advancements, Hamamatsu recognizes its responsibility in contributing to the positive impact of our solutions on humanity, society, and the environment. As the automotive industry embraces the era of autonomous driving and smart mobility, LiDAR stands as a cornerstone technology, and companies like Hamamatsu are instrumental in steering its course toward a future of enhanced safety, efficiency, and technological possibilities with a mindful consideration of the broader societal and environmental implications.

Luigi Ghezzi is Technical Marketing Engineer at Hamamatsu Photonics Europe

References

1https://caradas.com/levels-of-autonomous-driving-all-levels//

2https://www.linkedin.com/pulse/vehicle-lidar-market-insights-players-forecast-till-2030-60kue/