The electrification of transportation is at the forefront of innovation, and amidst the flurry of advancements in batteries and electric vehicles, one critical element often receives less attention—conductive additives. Carbon black is a pivotal component in lithium-ion batteries, enhancing their performance, stability and lifetime. Among the different types of carbon black, acetylene black stands out for its superior quality and sustainability.

The Role of Carbon Black in Lithium-Ion Batteries

In discussions about lithium-ion batteries, much attention is often placed on critical raw materials like lithium, cobalt and nickel. The crucial role carbon black plays is often overshadowed. Interestingly, one of the earliest patents for lithium-ion batteries involved the use of carbon black, specifically highlighting the benefits of acetylene black as a conductive additive.

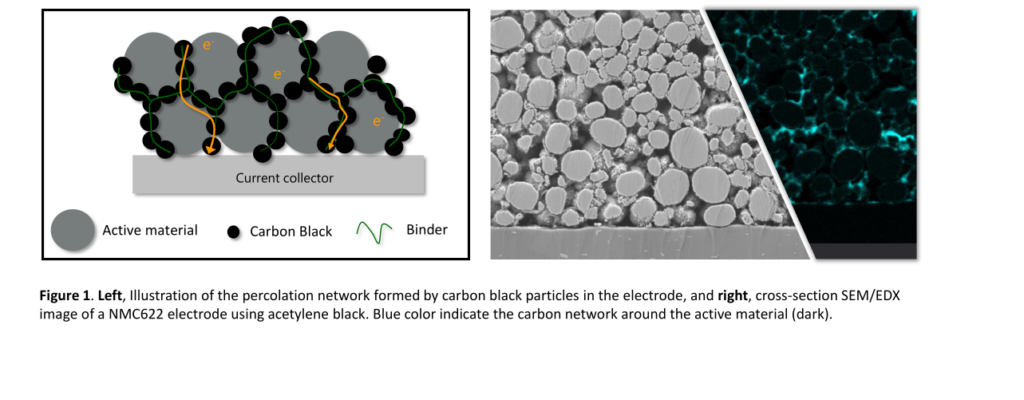

Carbon black works as a conductive additive, creating a three-dimensional percolation network that facilitates electron transfer from the active material to the current collector. This enhances the electrode conductivity during charge and discharge cycles, ultimately improving the battery’s energy density, cycle life and safety. To illustrate this, a graph depicting the percolation network of carbon black and an SEM image of carbon black particles provides visual clarity on how these additives function at the microscopic level.

In both anode and cathode electrodes, carbon black helps maintain electrical conductivity in the electrode and dissipates heat—crucial for preventing overheating and ensuring battery safety. For manufacturers, selecting the right grade of carbon black can make a significant difference in the overall performance and efficiency of the battery.

Production of Carbon Black: Processes and Raw Materials

Carbon black production involves several different processes, each using specific raw materials to achieve the desired properties. The manufacturing methods can be broadly classified into two main categories:

- Thermal-Oxidative Decomposition:

- Furnace Black Process: Uses aromatic oils on a coal tar basis or mineral oil.

- Degussa Gas Black Process: Uses natural gas and coal tar distillates.

- Lamp Black Process: Utilizes aromatic oils on a coal tar basis or mineral oil.

- Thermal Decomposition:

- Thermal Black Process: Uses natural gas or mineral oils.

- Acetylene Black Process: Utilizes acetylene gas as the primary raw material.

Each of these processes yields different types of carbon black, with unique characteristics that make them suitable for various applications.

Acetylene Black: High Purity, Low Environmental Impact

Orion, a global specialty chemicals company, operates the world’s longest-running carbon black plant. With a lineage that goes back more than 160 years to Germany, during which time it has become a global leader in carbon black technology,with four innovation centers produceing carbon black at 15 plants worldwide, offering the most diverse variety of production processes in the industry. Among the carbon black variants, acetylene black offers distinct advantages that set it apart. Produced from gaseous acetylene, acetylene black stands out due to its high purity and minimal environmental impact. At higher temperatures, exothermic decomposition of acetylene yields carbon and hydrogen, forming the basis of the acetylene black process. The manufacturing process used at Orion’s facilities—including the new production plant in La Porte, Texas—is cleaner compared to traditional methods, which use heavy oils resulting in emissions of sulfur oxides (Sox) and nitrogen oxides (NOx) – a very high CO2 footprint. The acetylene-based production process ensures a virtually zero-waste facility, with very low levels of NOx and sulfur oxides SOx emissions. This is an environmentally friendly choice that provides high-quality conductive additives.

The feedstock used in the company’s acetylene black production process is acetylene gas that is an industrial byproduct supplied by a neighboring facility that makes ethylene, which is used in polyester fibers, films, plastics and other materials for everyday products. If Orion did not take the acetylene gas, it would be burned for power generation, creating additional emissions. Instead, it upcycles the industrial byproduct and creates high-value conductive additives for the shift toward electrification.

Some acetylene-based conductive additives use calcium carbide as a feedstock. Because it is sourced from the coal industry, the feedstock has a significantly larger carbon footprint than Orion’s acetylene black.

Approximately 90% of the carbon is retained in Orion’s acetylene black, resulting in scope 1 emissions of only 200 kg CO2 equivalents per ton, compared with significantly higher emissions from other conductive furnace blacks. Such environmental benefits make acetylene black an appealing choice for electric vehicle battery manufacturers focused on sustainability.

Superior Performance: Low Internal Resistance, Cleanliness, and Long Cycle Life

Performance is a key consideration for cell manufacturers, and acetylene black excels on several fronts. One of the major performance benefits of acetylene black is its excellent percolation properties, which help reduce internal resistance within the battery. Lower internal resistance translates to more efficient energy flow, reducing power losses during use and improving overall energy efficiency.

Additionally, acetylene black’s highly pure nature ensures it does not compromise the longevity of the battery. Low levels of impurities mean minimal risk of contamination, which is crucial for maintaining stable electrochemical properties and extending the battery’s cycle life.

A Competitive Edge in Conductive Carbon Black

Orion Engineered Carbons is uniquely positioned in the conductive additives market, with over 160 years of history. Orion is the only producer of acetylene black in the Western hemisphere, with manufacturing plants strategically located close to their customers. The new plant in La Porte, Texas, will quadruple the company’s capacity for producing acetylene-based conductive additives, supporting the rapid growth of electric vehicle battery production in North America.

The company actively collaborates with battery manufacturers to tailor carbon black grades to specific needs, ensuring optimal integration into the production processes. By replicating customers’ process conditions, Orion provides tailor-made solutions that meet precise performance and quality requirements, thereby cementing its position as a reliable partner in the industry.

With a deep commitment to sustainability, the company is a partner in the HiQ-CARB Consortium, an EU-funded initiative focused on developing sustainable and high-quality carbon black additives.

Conclusion: Pioneering Sustainable Innovation

The shift to electrified mobility requires robust, reliable, and sustainable battery technology. Conductive carbon black plays an indispensable role in making this a reality. Acetylene black offers a compelling solution with superior purity, lower environmental impact and enhanced performance, meeting the demands of both battery manufacturers and the broader electric vehicle market.

Dr. Michael Rohde Director of Global Marketing Orion S.A.