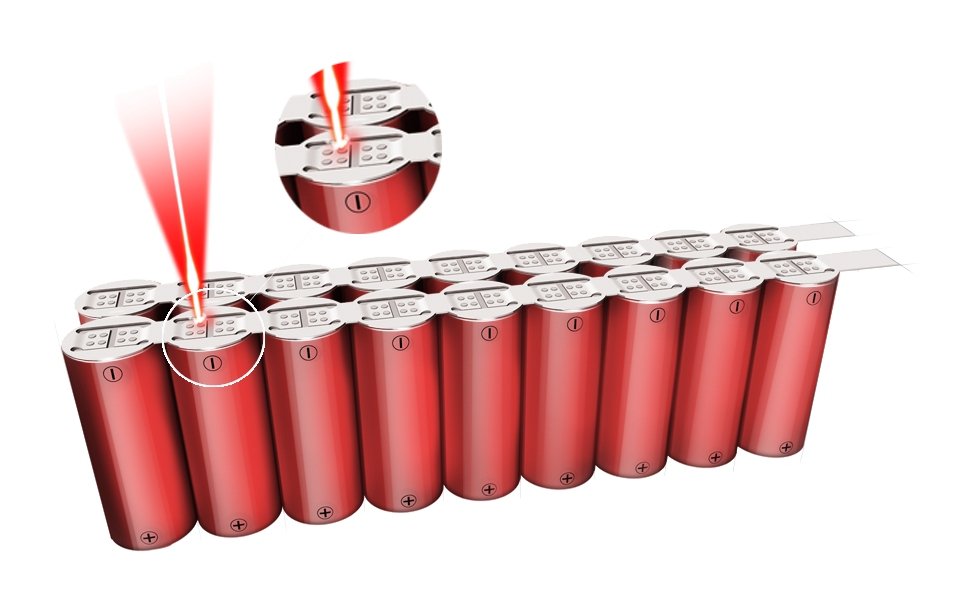

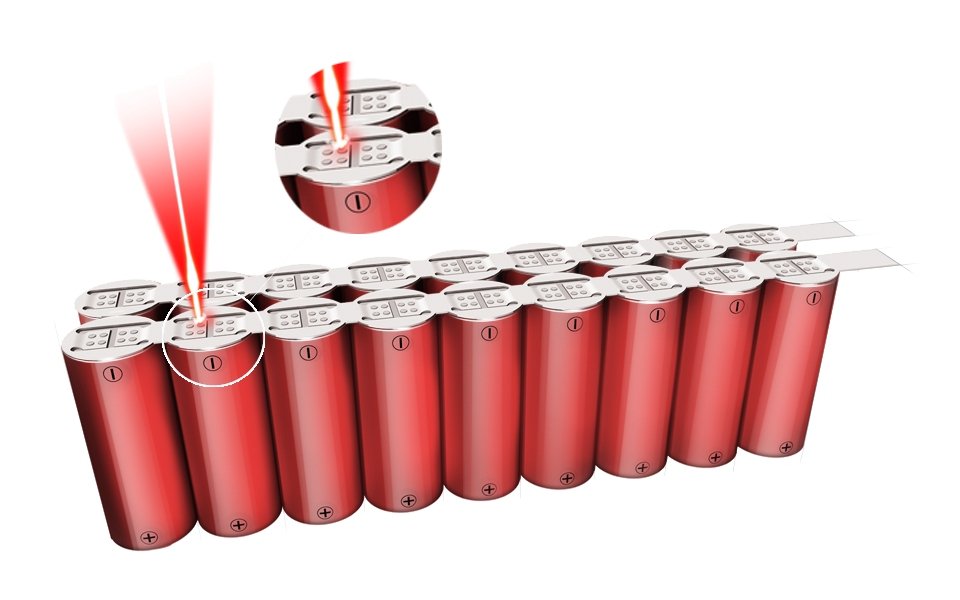

AMADA MIYACHI EUROPE announces a wide range of resistance and laser welding capabilities for manufacturing battery packs for hybrid and electric vehicles. AMADA MIYACHI EUROPE helps customers select the right tab to terminal connection welding system for batteries used in power train electrification of cars, trucks, buses and motorbikes. Also available are systems for welding battery packs used in cordless power tools and energy storage, including power walls.

AMADA MIYACHI EUROPE offers six laser welding technologies, four resistance welding technologies and micro-arc welding (also known as pulse-arc). Application experts recommend the right system based on the battery type, tab material and thickness, and required production volume. These systems are suited for integration into production lines. They help customers develop a stable and reproducible process and improve quality control.

AMADA MIYACHI EUROPE has supplied systems for welding battery modules to a variety of German and Central Europe manufacturers, including high-performance lithium battery module manufacturers located in The Netherlands and Germany.

Among the available technologies is the new MIYACHI EAPRO Jupiter Battery Welding system, ideal for welding cylindrical and prismatic batteries, pouch cells, and ultra-capacitors. The new module combines the advantages of resistance welding and laser welding into one complete battery tab welding system. The battery welding head uses an integrated tab down holder to ensure zero air gap between the tab and the battery pole. No additional tooling is required, resulting in fast, reliable welding of highly conductive materials like copper and aluminium. With weld speeds of less than one second and an integrated shielding gas and fume extraction nozzle, the module can be integrated into AMADA MIYACHI EUROPE’s systems platforms and automated in-line systems. An OEM version of this module is offered for integration into third party production lines