Advanced driver assistance systems based on 28nm CMOS technology:

Driving safely with reliable radar modules

Vjekoslav Matic & Thorsten Uhlenkamp

Reliable driver assistance systems are becoming increasingly important – not just for driving comfort but also for road safety. They are based on numerous sensors, though radar sensors such as the CTRX8181 radar transceiver from Infineon offer many advantages.

Advanced Driver Assistance Systems (ADAS) have become increasingly important in recent years. After all, ADAS not only increase driving comfort but also road safety and can even save lives. In addition, for certain vehicle types including trucks, systems such as the Electronic Stability Program (ESP), the Lane Departure Warning System (LDWS) and the Advanced Emergency Braking System (AEBS) are now mandatory, and many more will follow in the coming years.

For over 15 years, Infineon has been an important driver for the further development of driver assistance systems. With the introduction of the RASIC™ CTRX8181 transceiver, Infineon now enables even more reliable ADAS: the sensor is the first product in a series of new 76 to 81 GHz radar MMICs based on 28nm CMOS technology.

Function and benefits of ADAS

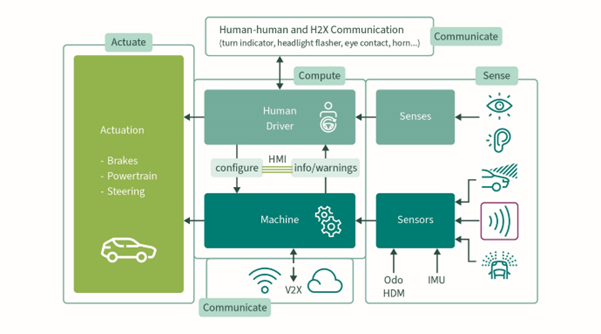

Driving assistance systems are primarily based on environmental and vehicle sensors, which record a lot of useful information. This information includes the vehicle’s surroundings, in other words the road, other vehicles, the infrastructure and obstacles, and the vehicle itself, for example its exact position and orientation, as well as its speed and direction of travel (Fig. 1). The collected information is sent to one or more driver assistance control units where they are evaluated – centrally or decentrally. Then, the computer unit either sends warning signals to the driver or actively intervenes via electromechanical actuators, such as steering or speed control.

Figure 1 The principle behind an ADAS: sense, compute, actuate

The capabilities of a radar sensor

Radar sensors in particular offer several advantages when it comes to implementing ADAS. Compared to other technologies, the sensors are less susceptible to weather conditions and can also reliably record data in rain, snow, fog, smoke, and dust (Fig. 2). They also feature a long range and detect objects at several hundred meters. In combination with the color and object recognition properties of camera sensors, radar sensors thus enable reliable object classification for ADAS applications due to their ability to directly detect objects by measuring their distance, angle, and speed.

Figure 2 : Even in fog, radar sensors can reliably detect people and obstacles

Radar sensors for automotive applications

Radar sensors, or more precisely millimeter wave radar sensors, have been used in automotive electronics for many years. They work in a similar way to conventional radar systems; however, they use waves in a higher frequency range, between 24 GHz and 81 GHz. This enables a higher resolution and accuracy. As a result, they detect both static and fast-moving objects at short and long distances. Most of today’s automotive radars are based on the FMCW principle (Frequency Modulated Continuous Wave). In contrast to pulse radars, this principle is cost-optimized, highly integrable and can still be implemented with sufficient accuracy. FMCW radars are used in the automotive industry for distance measurement and collision avoidance.

FMCW radar – how does it work?

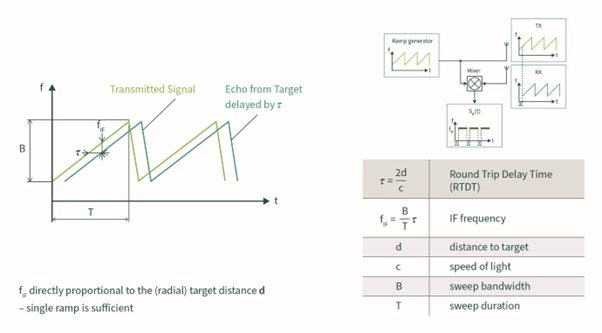

The radar emits a signal via one or more transmitting antennas that represents a linear frequency-modulated ramp at a frequency of 77 GHz. The signal is reflected when it hits an obstacle, for instance another car, a truck, or a pedestrian. Reflected signals are then received by one or more receiving antennas and forwarded to the receiving section of the radar

Figure 3. Functionality of an FMCW radar

The propagation time of the signal results in a frequency difference between the transmitted and received signal that is proportional to the distance. The signal is mixed down to an intermediate frequency receiver chain by a mixer and then digitized. Digital signal processing uses Fast Fourier Transformation (FFT) to determine the frequency and therefore the distance to the target. In addition, the phase of the signal is determined, which provides information about the speed of the target through the Doppler effect.

Due to the relative phase difference between signals from several receiving antennas, the radar can also determine the horizontal (azimuth) or vertical (elevation) angle of incidence of the signal. This means it can calculate the exact position of the target relative to the sensor.

The quality of the signal is influenced by ramp linearity and phase noise. Ramp linearity refers to the continuous increase in frequency of the radar signal to capture range and speed information. On the other hand, phase noise refers to unwanted fluctuations in the phase of the signal that may affect the accuracy of target localization. The number and arrangement of the antennas as well as the distances between them determine the field of view and the resolution of the sensor. A larger number of antennas and their positioning increases the accuracy of target localization and enables a higher resolution.

A radar sensor can be referred to as 4D radar as it simultaneously determines distance, velocity, horizontal and vertical relative position of the target in all dimensions. The range resolution is also determined by the bandwidth of the frequency ramp. To increase the accuracy of the sensor, the antenna arrangements with multiple transmitter antennas require the individual transmitter signals to be separated/recognized for each receiver channel.

Requirements that a radar sensor must fulfill

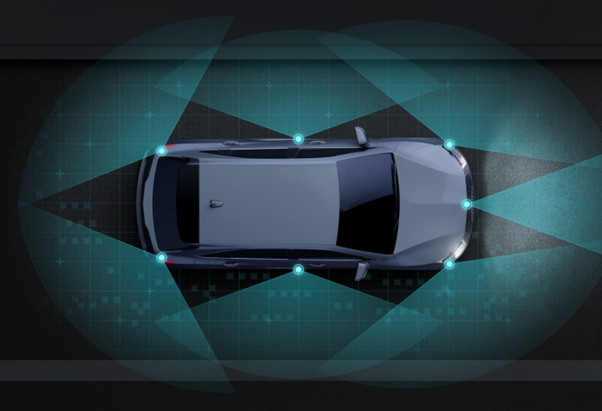

New radar sensors used in modern vehicles must fulfill several requirements. While Long Range Front Radar (LRR) is designed for a long range of up to 300 m, Corner Radar (CR) requires larger aperture angles of over 150 degrees at ranges of 100 to 150 m (Fig. 4). The effectiveness of the digital signal processing plays a crucial role in determining the range. This determination is influenced by the reflectivity of the target for 77 GHz signals (Radar Cross-Section, RCS) and the RF characteristics of the transceiver. Weakly reflective targets such as pedestrians pose a greater challenge for the sensors than strong reflectors like cars and trucks. Therefore, a good signal-to-noise ratio is important for both sensor types for reliably separating strong and weak signals. Digital signal processing and object tracking are important functions that are carried out on the microcontroller integrated in the sensor before the data is output via a network interface.

Figure 4 Typical arrangement of radar sensors

In addition to the technical requirements, radar sensors must also comply to the strict quality criteria of automotive electronics. As part of the ADAS system, they must also meet the even stricter requirements of ISO26262 in functional safety.

Highly integrated radar sensor from Infineon

The Infineon RASIC CTRX8181 based on 28nm CMOS technology fulfills these requirements and enables the wider use of advanced and reliable ADAS functions in vehicles. The CTRX8181 complies with the highest quality requirements and fulfills safety aspects up to Automotive Safety Integrity Level (ASIL) C. In addition, the 1dB compression point of the CTRX8181 also contributes to the reliability of the radar sensor.

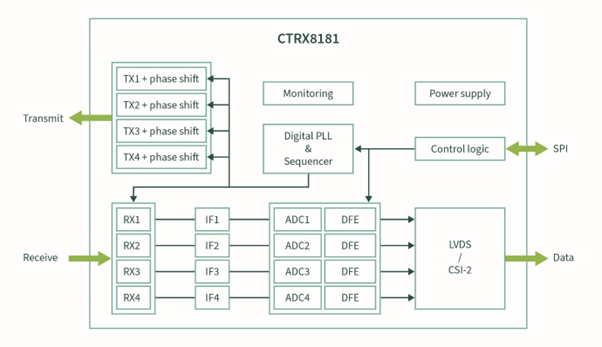

The radar sensor MMIC in detail

The CTRX8181 (Fig. 5) is a highly integrated radar sensor consisting of four transmit channels with dedicated phase shifters, four receive channels including frequency conversion, analog-to-digital converters, and digital filters as well as the phase locked loop (PLL) for signal generation and sequence control. The digitized radar data is transmitted to the microcontroller via the LVDS or CSI-2 interface. Additionally, the CTRX8181 has continuous monitoring functions, which also serve to comply with the ASIL-C standard.

Figure 5 Block diagram of the CTRX8181

The signal-to-noise ratio of the CTRX8181 has been improved even further: up to 25 percent compared to the current standard. This enables even greater ranges and wider aperture angles. For a front radar, that means an increase in range from 250 m to 300 m.

No chance for ghost targets

Another special feature of the CTRX8181 is its ability to process high input signal levels without distortion: For instance, corner radars are often mounted behind the bumper, which can lead to reflections with high signal levels due to the nature and paintwork of the bumper. With its high 1dB compression point, the CTRX8181 can receive these high signals without overloading the receive signal chain and without revealing ghost targets in the radar data. Furthermore, the phase-locked loop (PLL) of the CTRX8181 enables even shorter ramp generation response times: up to four times shorter than currently available sensors. Therefore, it is possible to increase the efficiency or the pulse repetition rate of the sensor. The ramp linearity of the phase-locked loop has also been improved further. With the help of integration amplification over several ramps, the target localization and separability of pedestrians and objects is further improved.

CTRX8181 enables next-generation radar sensors

With the CTRX8181 millimeter-wave radar sensor, Infineon addresses the high requirements of the automotive sector and supports manufacturers in the development of modern driver assistance systems. With its outstanding signal-to-noise ratio, excellent 1dB compression point and fast and accurate phase locked loop, it enables reliable object separation and detection. This is necessary for the protection of road users that are otherwise difficult to detect and unprotected, such as motorcyclists, cyclists, or pedestrians.

Vjekoslav Matic is Senior Director Technical Marketing for Automotive Radar at Infineon

Thorsten Uhlenkamp is Senior Manager, Product Marketing for Automotive Radar MMICs at Infineon