r Christophe Bianchi

Closing the Gap Between Design and Reality

The world’s automakers are racing to launch new EV models, and many of the engineering challenges around EVs centre on the electric battery and its management system: bringing together hardware and software components, the BMS (Battery Management System) independently ensures the smooth, safe operation of a battery-powered (or hybrid) vehicle at optimal performance conditions.

Modelling & Simulation addresses multiple challenges in the development of batteries and battery management systems for EVs, and more specifically address the following challenges:

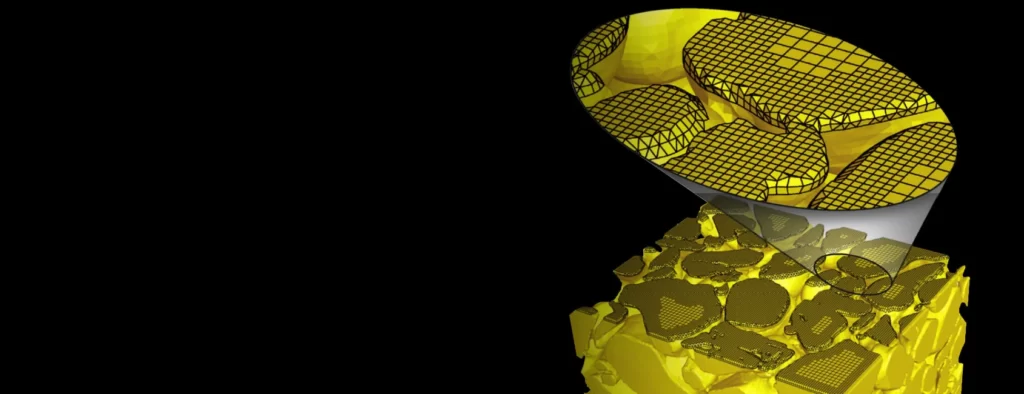

Battery Cell and Electrode Design & Manufacturing

Electrochemistry is the physics behind how a battery operates and performs. Electrochemistry simulation supports from the manufacturing of the battery cell to predicting age and lifetime. Cell manufacturers are tasked with the challenging job of storing as much power as possible, while reducing size, weight and cost. Accurately simulating electrochemistry before the manufacturing process helps with materials property selection and electrode structure design.

To determine the relevant performance characteristics of the battery cells, an electrochemical-thermal simulation will ensure temperature uniformity through fully coupled, multiphysics and multiscale models, whilst verifying heat generation and charge density response curves.

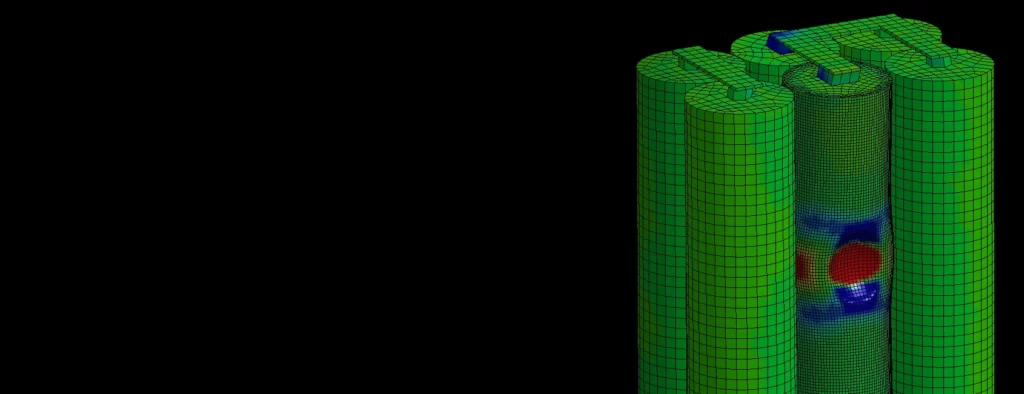

Battery Pack and Modules Thermal Management

Batteries are extremely sensitive to temperature. Thermal management is critical to reduce temperature variations and to avoid thermal runaway. As a battery’s temperature increases, its rate of chemical reactions and performance can improve. However, at one point, a rise in temperature may cause permanent damage. In order to design and validate the most cost/function effective cooling system, multiple physics must be jointly simulated such as Electro-Thermal coupling, Electrochemistry modelling, analysis of thermal runaway and thermal propagation, fluid dynamics of the coolant…

The number of optimisation parameters can be so large that it may makes sense to use AI-powered optimisation methods to identify the best design. These optimisation methods rely on ML algorithms that are trained on combination of physical data (lab tests) and virtual data (simulation results) where multiparameter optimisations provide the design engineers with a range of optimal designs to choose from.

Once the best design has been identified and validated, a reduced-order-model (ROM) can be created: it is a digital twin of the battery that can be loaded on a control unit (AI on the edge) to perform continuous monitoring and validation during the lifetime operation of the batteries.

Battery Structural Reliability

Batteries can be exposed to a variety of situations that can compromise their safety. To ensure battery durability,

In order to build the safest battery on the market, there is a large set of industry standards that a battery design needs to be validated against; such standards include SAE J2464, UL 2580, IEC 62619, SAND 2017-6925 and NASA JSC 2073. Simulate and optimize housing designs and reinforcements to build the safest battery on the market.

To meet these stringent requirements, designers must simulate and optimize housing designs and reinforcements with respect to Impact and Drop Test, Thermal Stress, Random Vibration and Fatigue, considering the specifics of Advanced Materials.

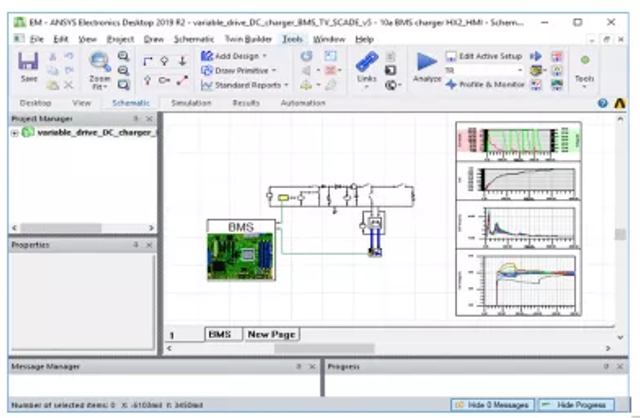

Battery Management System

Battery management systems (BMS) play a critical role in today’s electric vehicles. Optimizing the development, test & verification of these sophisticated systems offers significant time, cost & quality advantages for BMS development teams.

This includes ensuring Functional Safety for the BMS system, development and validation of critical Embedded Software utilizing the software controller, intelligently monitoring the battery’s operating conditions and overseeing its safe operations and achieving a System-Level perspective on how the BMS and battery will perform throughout their entire life cycle.

Battery Electromagnetic Interference (EMI) Simulation Testing and Design

High-frequency EMI noises can cause crosstalk between a high-voltage power circuit in a battery array and a low-voltage control circuit in a battery management system. Electromagnetic simulation can be used to predict electromagnetic interference (EMI) emissions and susceptibility early in the battery design process or be used to conduct root cause analysis for existing EMI challenges in a battery system. These predictions and analysis can help optimize the EMI filter design and reduce hardware testing costs for compatibility tests.

The critical steps for EMI noise prediction and EMI validation are Early detection and mitigation of EMI noises before battery production, and EMI filter design and optimization.

This can be achieved with accurate battery cell modelling (using EIS data-based battery cell/module models can convert frequency domain testing data into a time domain battery impedance mode), accurate parasitic components modelling (using FEA-based battery parasitic modelling to extract parasitic elements of battery package components using geometric information and material properties) and system-level modelling (where System level virtual compatibility testing can be used for virtual testing of compatibility standards or be used for root cause analysis of real EMI challenges for existing product)

“Because the BMS manages and controls all battery functions — safeguarding against such problems as overheating — it is critical that our solutions meet the highest functional safety standards, including ISO 26262. Unless we meet these standards, we will not be able to supply products to the global automotive market. We rely on Ansys ‘medini analyze’ to manage and automate the process of certifying our battery management systems. By taking significant time and costs out of the development cycle, ‘medini analyze’ positions LiTHIUM BALANCE to compete in the global automotive battery market. It has absolutely been critical for the analysis and quantification of our safety goals.”

Claus Friis Pedersen R&D Director / LiTHIUM BALANCE A/S

Forecasts for the growth of autonomous vehicles is optimistic. This optimism depends on the confidence of the customers insurance companies and regulators. Modern vehicles require full awareness of their surroundings, detecting their environment using a number of technologies such as cameras, radar and sensors. With all the sensors switched on in a single trip the vehicle is collecting terabytes of data. In such a complicated electromagnetic environment its critical to understand in simulation all aspects of the conditions

What is the Ansys approach to these complexities?

Dr. Bianchi

One of the most important current trends in the automotive industry is the development of advanced driver assistance systems (ADAS). Due to the ever-increasing complexity of ADAS, the safety validation of such systems is a major challenge. New methods have to be developed, as the previous certification and approval methods are not suitable for this use case.

The required mileage needed to proof the probability of failure of the system is impossible to reach in field operational tests, as it is estimates that autonomous vehicles would need to be driven for billions of miles to show performance across real-world scenarios.

Additionally autonomy increases the level of complexity of the embedded software by at least an order of magnitude: Modern cars have roughly 100 million lines of embedded software code. Estimates suggest that AVs will need 1 billion lines of code.

And time to production is limited whilst demand is high: With 45% of vehicles sold by 2030 projected to be highly automated, significant automation improvements are required in the next 10 years.

With so many technical barriers between modern vehicle systems and full automation, simulation is necessary to solve critical design challenges in the areas of autonomy system definition, hardware development, software development and especially system validation. Therefore, simulation is a key component to find critical scenario characteristics for safety function testing, validation, and even certification of highly automated driving systems. One of the greatest challenges here is the high number of simulations needed for testing, especially for very rare events (logical scenarios with low probability of failure 10^-6)

When it comes to Autonomous Vehicles, there are 4 major categories of engineering challenges to consider:

- Autonomous Sensor Development,

- Autonomous Software Development

- Autonomous System Development

- Autonomous System Validation

High-Performance Sensor Design for All Conditions

Sensors are critical components that provide the information autonomous vehicles need to make intelligent and safe decisions. They must reliably deliver high performance capabilities and function in a wide range of adverse operating conditions, including rain, ice and snow. Simulation is proven to enable engineers to improve sensor performance, determine optimal vehicle integration configurations and examine their behaviour across a wide range of operational scenarios. With such safety-critical systems, the most accurate, physics-based simulation tools are required. Whether it is for Lidar where optomechanical, thermal interactions and an optical materials properties library, enable rapid emitter and receiver design and placement optimization ; for Camera where vision performance analysis and high-fidelity lens transfer functions are required for optomechanical optimization, placement and validation ; Radar where accurate and fast electromagnetic simulation allow engineers to rapidly analyse radar system performance in complex, dynamic scenarios and improve the accuracy of their response to potential hazards ; or in the testing of Perception Software when identifying potential vulnerabilities in AV perception systems, by finding and categorizing edge cases where these systems might exhibit unsafe behaviour.

Accelerate Embedded Software Development and Validation

Model-based methodology and solutions accelerate autonomous vehicle and ADAS features software design and validation at the very earliest stages of AD development and offer the auto-generation of certified/qualified code, that complies with industry standards including ISO 26262 ASIL D, DO-178C and others.

It all starts at the System Architecture level: The development of embedded software for AD systems begins by creating an architecture model of the automated driving system $. This intuitive modelling tool generates a system-level architectural model that graphically shows the main function blocks for the AD system.

On this Architectural model, model-based software development assist the designers in designing control systems to automatic code generation for industry standards such as ISO 26262 and DO-178C.

And closed loop simulator solution, with APIs and middleware, enables auto-generation of safety-certified code that is target compatible for RTOS integration.

The validation, at each level of verification from SiL (Software in the Loop) to HiL (Hardware in the Loop) and finally DiL (Driver in the Loop), supports all testing and verification activities for the AD embedded software model.

Safe and Cybersecure Autonomous Vehicles

With model-based safety and cybersecurity solutions, end-to-end traceability can be established. Compliance with existing standards (such as ISO 26262, ISO 21448, ISO 15408 and other emerging standards) can be demonstrated, saving up to 50% on development time compared to more manual approaches. Our simulation solutions focus on:

Functional Safety (FuSa): Integrating advanced safety analysis methods with model-based safety analysis, is required to deliver end-to-end traceability and compliance with safety standards such as ISO 26262.

Cybersecurity: in order to identify cyber vulnerabilities, it is essential to integrate architectural and functional design models with cybersecurity analysis methods.

Safety of the Intended Functionality (SOTIF): once again, simulation is required to undertake systematic causal analysis of SOTIF hazards and compliance with safety standards such as ISO 21448.

Rapid Autonomous System Validation

Testing strategy has to be defined that includes detailed and realistic world modeling and scenario generation and must incorporate high-fidelity sensor simulations. From this, software-in-loop (SiL), hardware-in-loop (HiL) and driver-in-loop (DiL) analyses can be performed.

Software-in-Loop: Incorporating high-fidelity physics-based sensor models enables open loop software testing, model coverage and verification of the software implementation against key performance indicators and test plans.

Driver-in-Loop: With VR, the simulation environment provides live interaction between the user, virtual actuators and vehicle embedded software. This captures finger motions and heatmaps, a full cockpit user experience, reflection studies and HUD performance very early in the design process.

Hardware-in-Loop: Automatic code-generation solutions generate RTOS independent vehicle and sensor models on real time targets that provide continuity from design to verification, delivering test reproducibility and analysis of edge and worst-case scenarios.

In conclusion

Great advances aren’t made in baby steps. They happen in big, bold leaps. To push innovation forward faster and achieve their most ambitious engineering goals with confidence, visionary companies partner with Ansys.

“The advanced reliability methods available in Ansys optiSLang enable Mercedes-Benz AG to make a safety statement for Level 3 ADAS using scenario-based simulation.

Thanks to the efficient and robust methods, the number of necessary traffic simulations could be dramatically reduced in comparison to Monte Carlo Sampling.

The Ansys optiSLang postprocessing, with which detailed analyses of the results could be carried out, should also be emphasized.”

Maximilian Rasch, ADAS validation engineer / Mercedes-Benz AG

Zafer Kayatas, ADAS validation engineer / Mercedes-Benz AG

Christophe Bianci – Chief Technologist, Ansys